Review on the progress in the production of aromatic hydrocarbons by co-catalytic pyrolysis of biomass and plastics

-

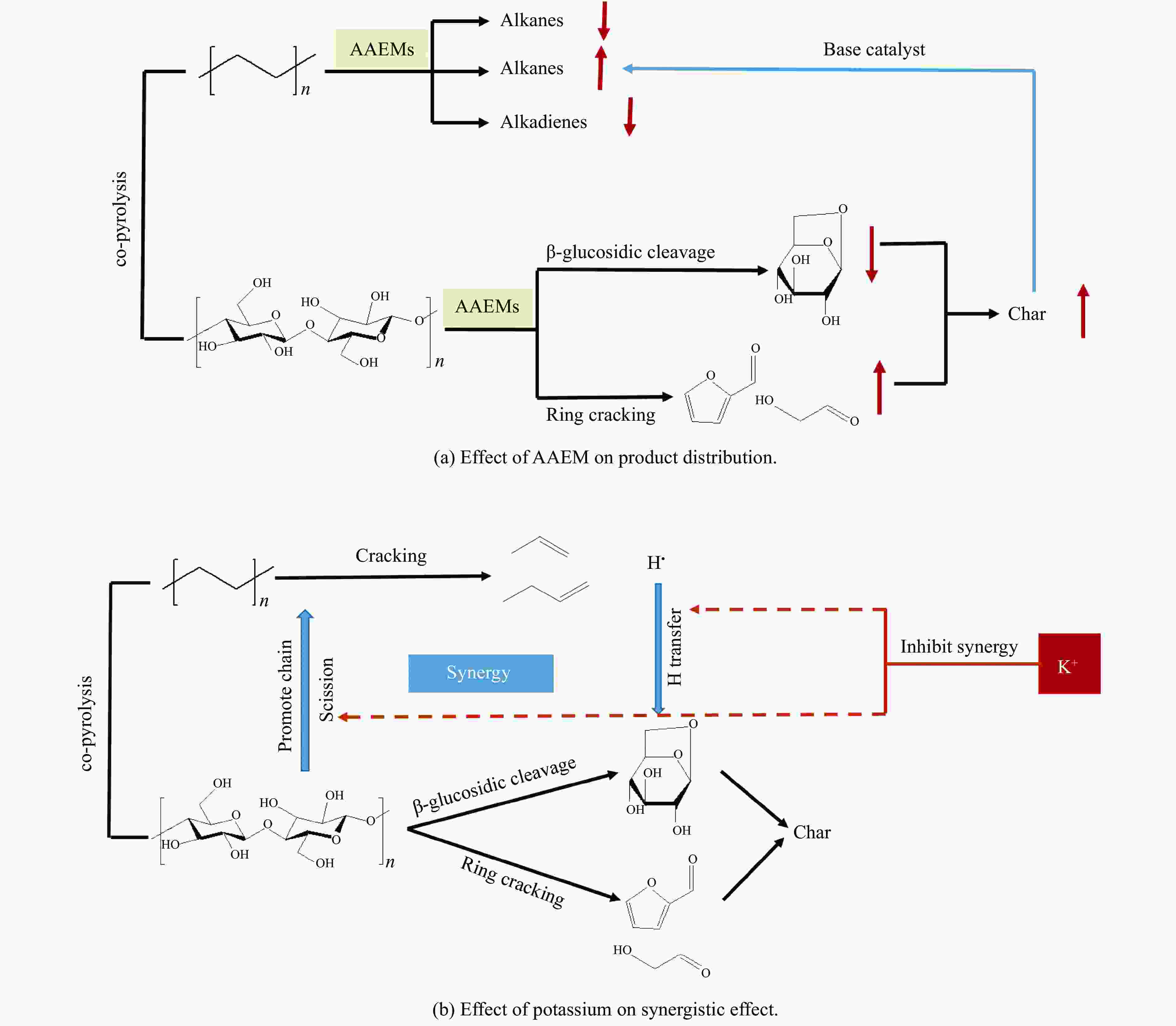

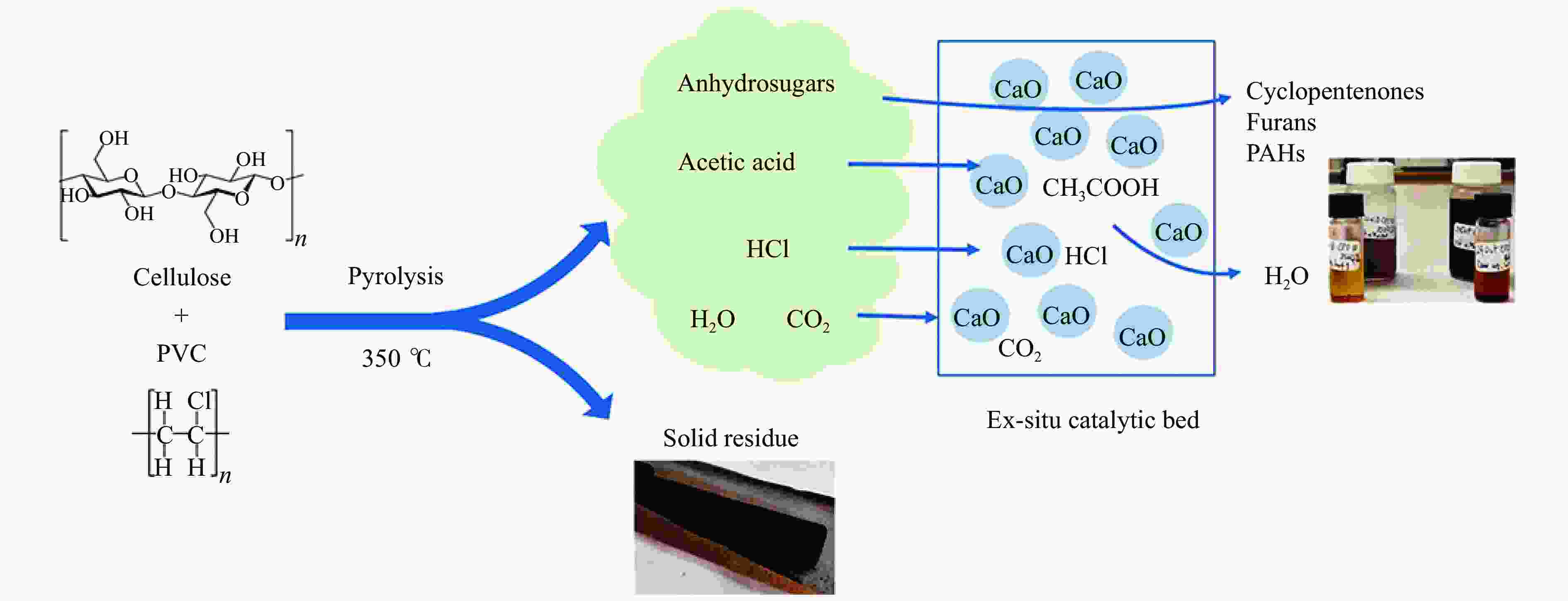

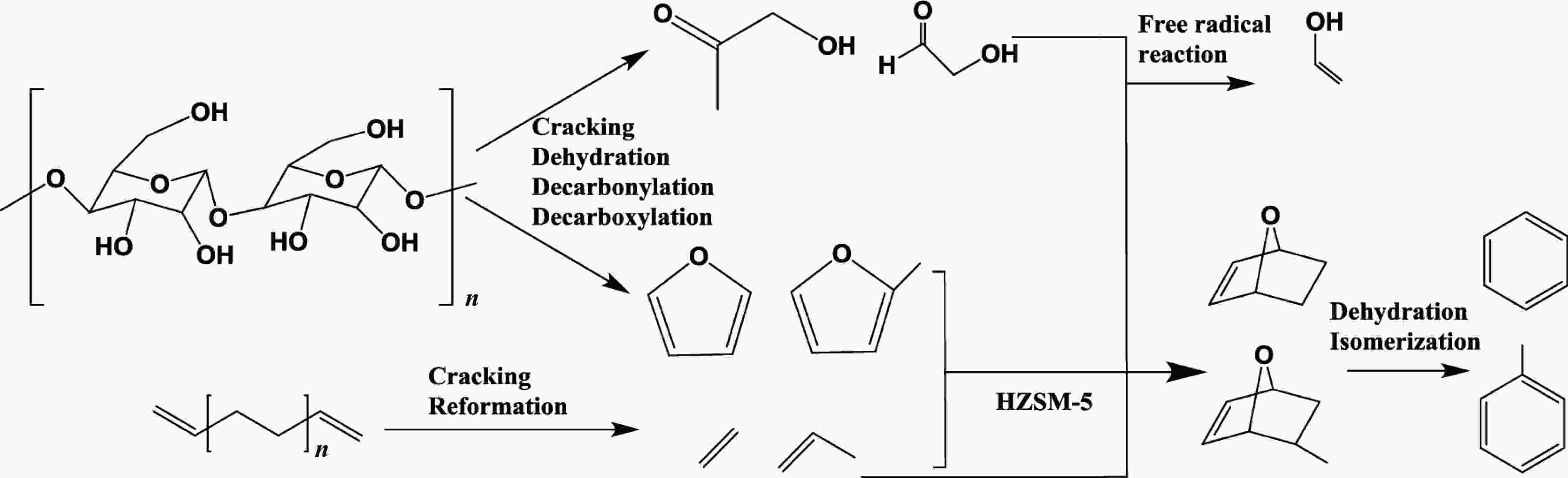

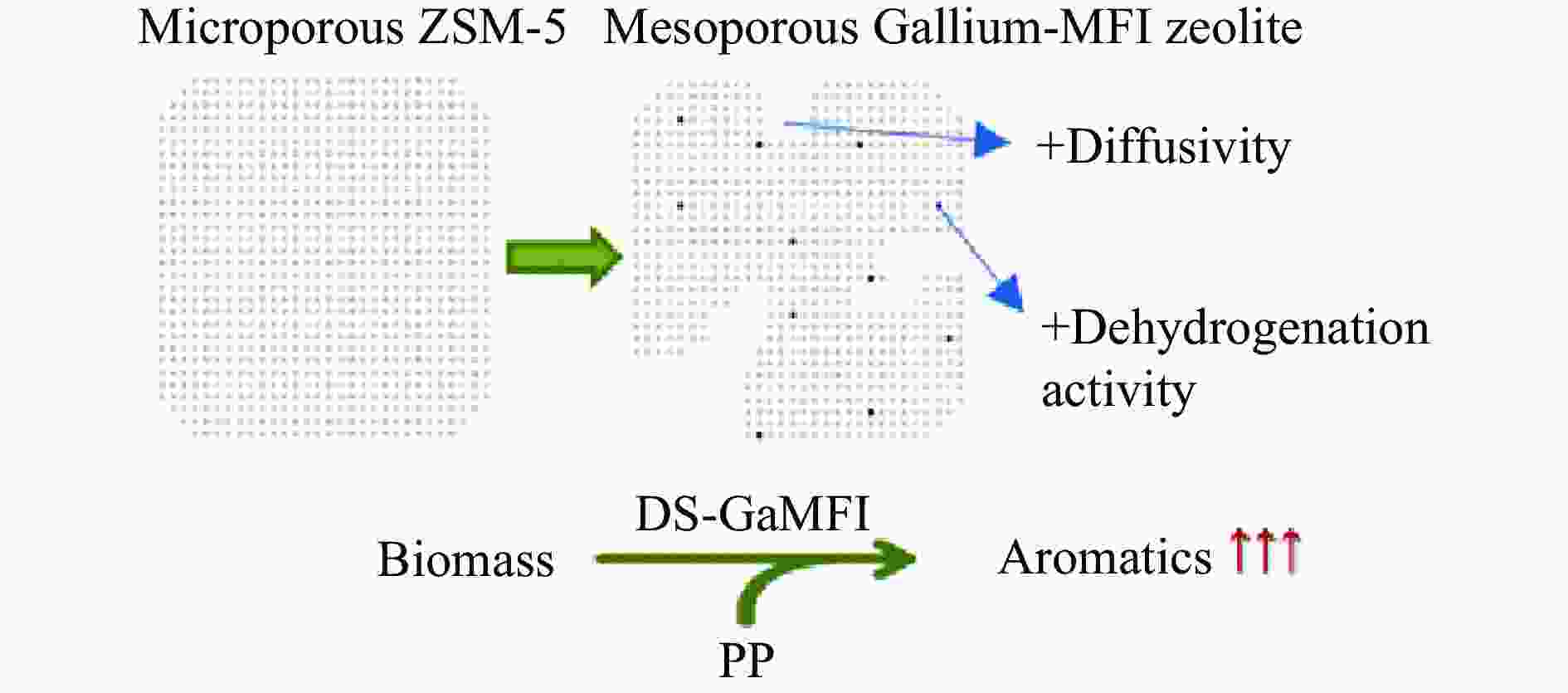

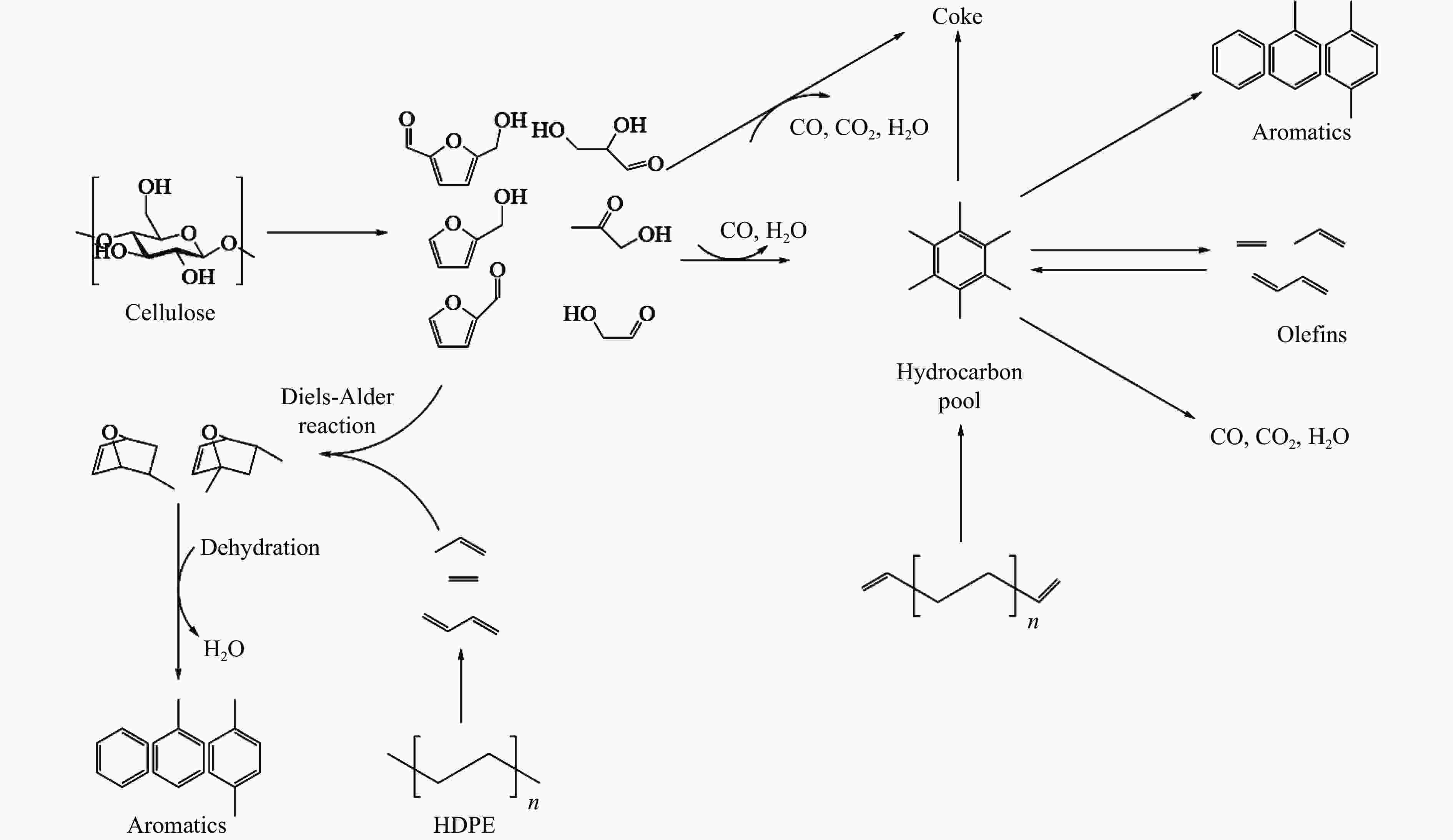

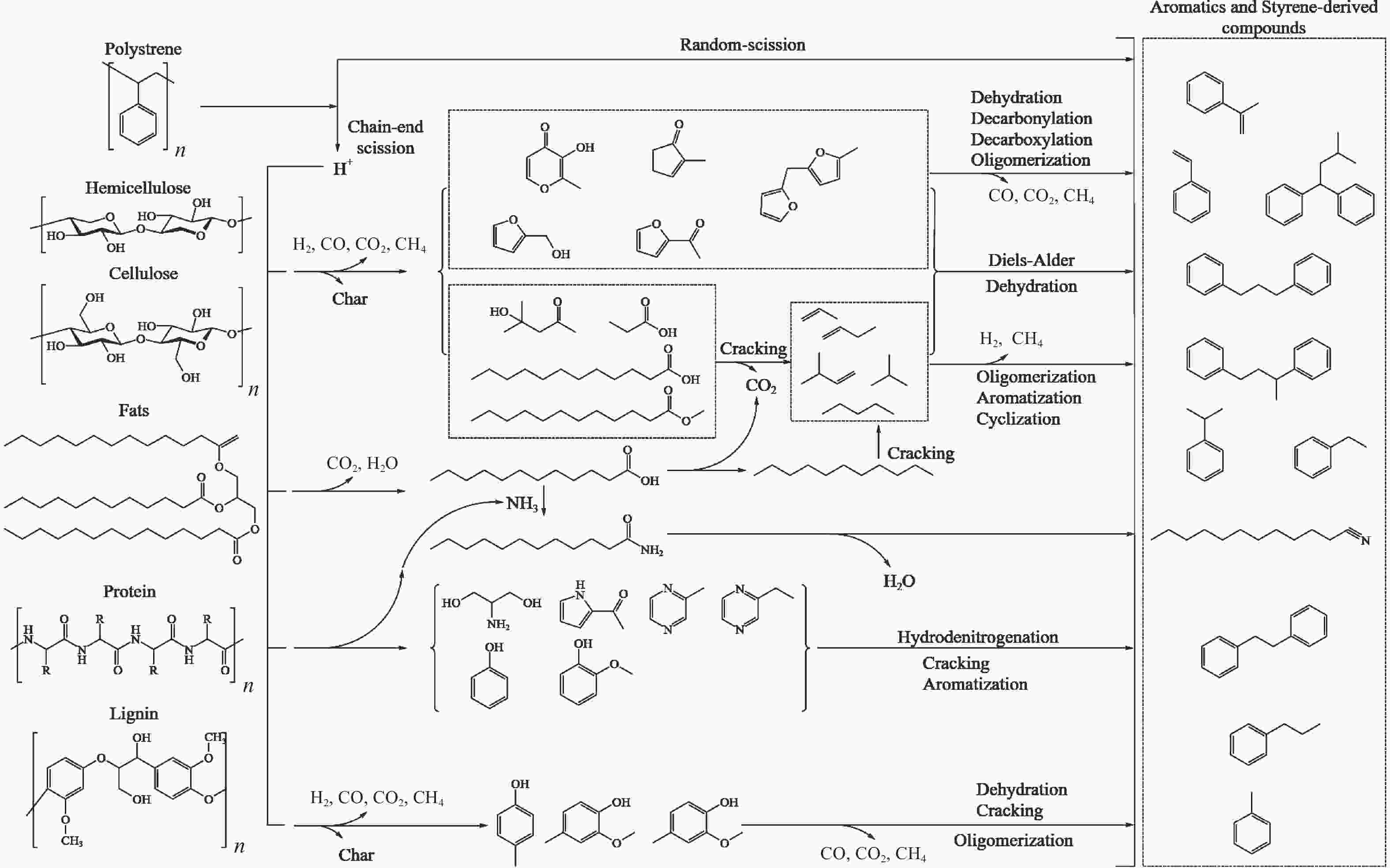

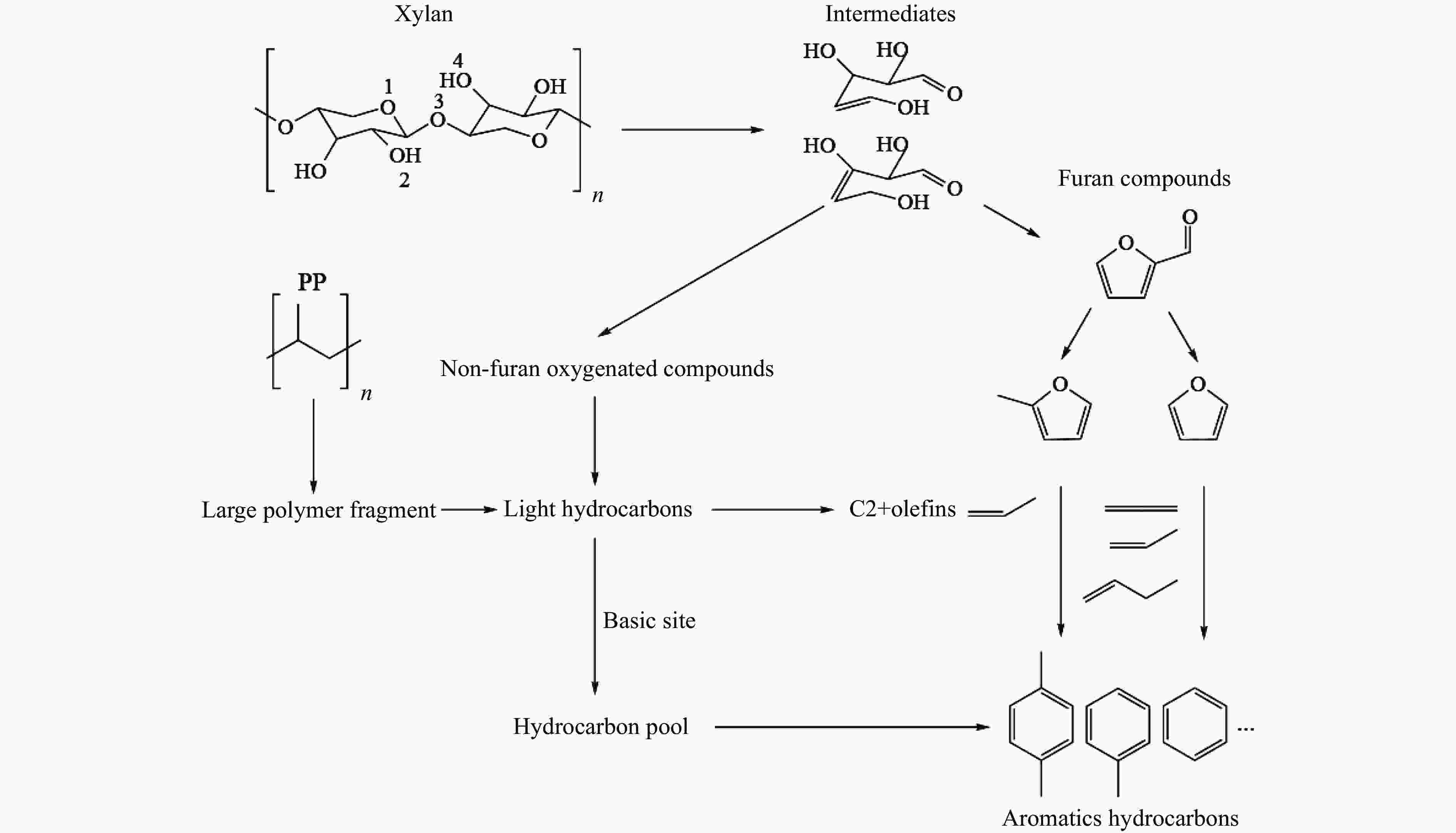

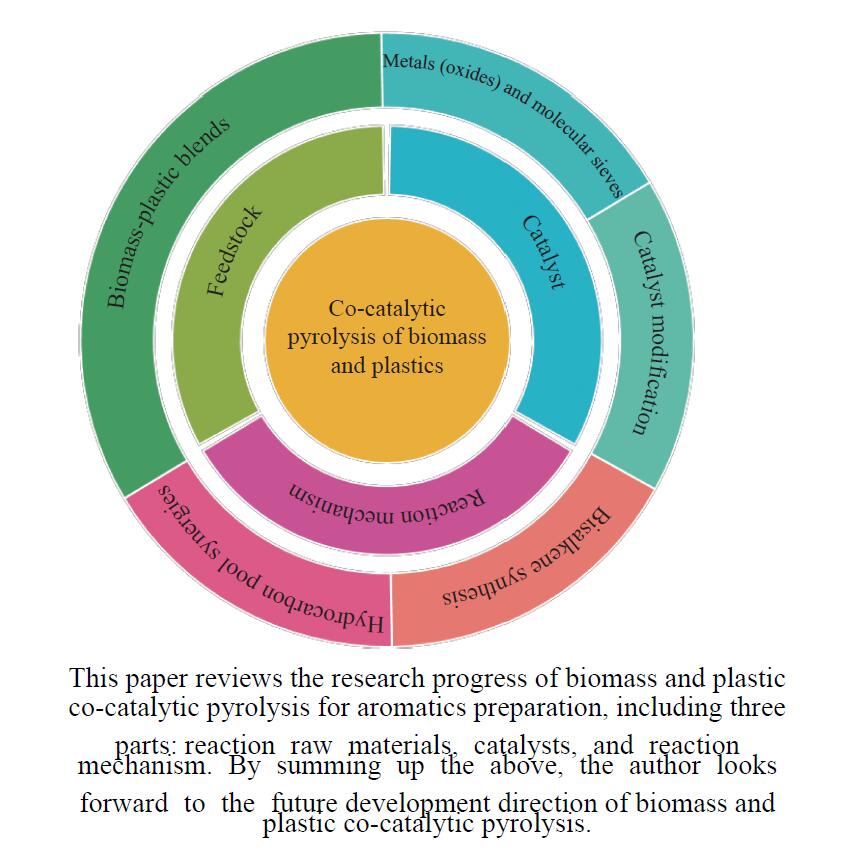

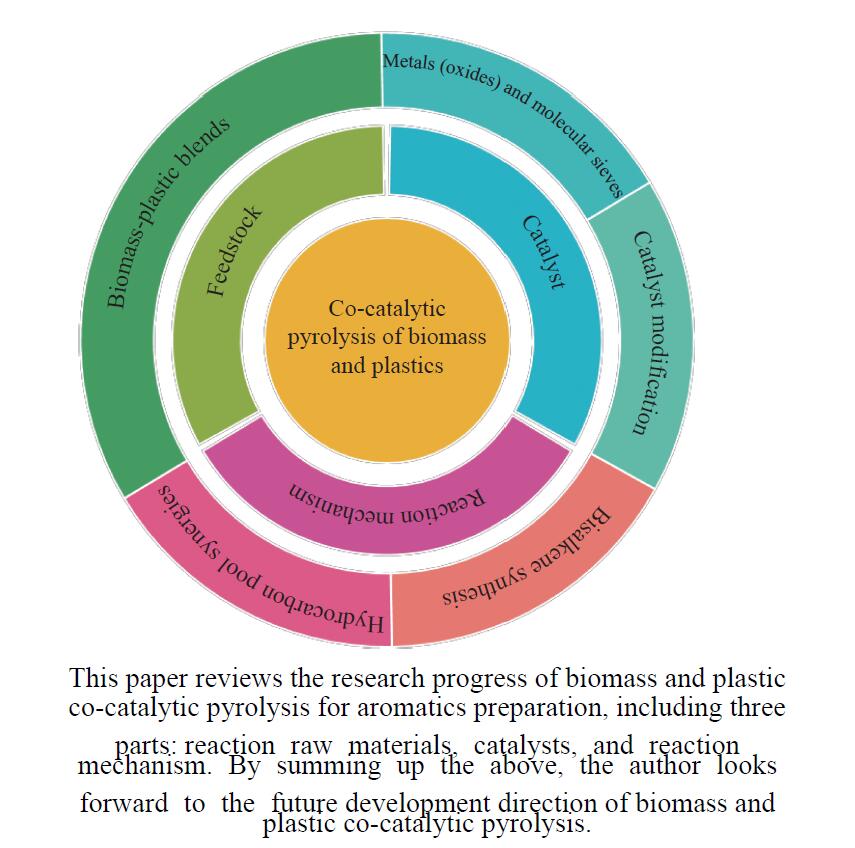

摘要: 芳烃,尤其苯、甲苯、二甲苯(BTX)等单环芳烃,是化工行业重要的基础原料,主要来源于化石燃料的催化重整与热裂解。生物质与塑料共催化热解制芳烃具有高效、环保、低成本、高选择性等优点,可以解决因生物质富氧、贫氢的特点造成热解产物氧含量高、芳烃收率和选择性低等问题。本工作主要综述了生物质与塑料共催化热解制备芳烃化合物的研究进展,介绍了共催化热解反应原料类别,重点论述了共催化热解反应催化剂,总结归纳了共催化热解双烯合成、烃池协同等反应机理。展望了生物质与塑料共催化热解未来的研究重心与发展方向,即通过研制高活性、高稳定性的改性分子筛催化剂来提高芳烃产率。Abstract: Aromatic hydrocarbons, especially monocyclic aromatic hydrocarbons such as benzene, toluene, and xylene (BTX), are important basic raw materials in the chemical industry, which are mainly derived from the catalytic reforming and thermal cracking of fossil fuels. The co-catalytic pyrolysis of biomass and plastic to produce aromatics has the advantages of high efficiency, environmental protection, low cost, and high selectivity. It can solve the problems of pyrolysis products such as high oxygen content, low aromatics yield, and low selectivity, which are caused by the characteristics of biomass rich in oxygen and poor in hydrogen. This article reviewed the research progress of co-catalytic pyrolysis of biomass and plastics to prepare aromatic compounds. Firstly, the types of raw materials for co-catalytic pyrolysis were introduced, and then the co-catalytic pyrolysis catalysts were emphasized. The reaction mechanisms of co-catalytic pyrolysis of biomass and plastics, such as the synthesis of dienes and hydrocarbon pool synergy were summarized. Finally, the future research focus and development direction of co-catalytic pyrolysis of biomass and plastics were proposed, which is developing the highly active and stable modified molecular sieve catalysts in order to improve the aromatics yield.

-

Key words:

- biomass /

- plastic /

- co catalytic pyrolysis /

- aromatic hydrocarbon /

- catalyst

-

表 1 生物质与塑料共催化热解制备芳烃化合物常用原料、催化剂、反应条件、催化性能

Table 1 Common raw materials, catalysts, reaction conditions, and catalytic performance for preparation of aromatic compounds by co-catalytic pyrolysis of biomass and plastics

Raw material Catalyst Reaction conditions Bio-oil/

Aromatic hydrocarbon yield

/%Main products in bio-oil Ref. biomass plastic ratio of raw material to mass ratio of raw material to catalyst pyrolysis temp.

/℃catalytic temp.

/℃Cellulose HDPE Na 1∶1 550 550 olefin [40] Bamboo LDPE CaO 1∶1 1∶2 450 550 9.76a alkanes, olefins [37] Cellulose PE MgO 1∶1 4∶1 700 700 olefin, aromatics [41] Cellulose PVC CaO 19∶1 1∶1 350 350 24.9a PAHs [42] Bamboo LDPE CeO2 1∶1 1∶2 450 550 hydrocarbons [37] Poplar wood-polypropylene composite Fe2O3 1∶1 1∶4 600 600 hydrocarbons [44] Chili straw PP HZSM-5 1∶1 1∶1 750 750 17.34b alkanes, olefins [50] Cellulose LDPE ZSM-5 1∶1 1∶15 650 650 47.46b aromatic [52] Wheat straw Municipal Plastic Waste β-zeolites 1∶1 2∶1 550 550 32.5b aromatic [54] Mandarin peel HDPE HY 1∶1 1∶1 600 600 5.06b [55] Poplar wood-polypropylene composite HUSY 1∶1 1∶4 600 600 60.83b aromatic [56] Wheat straw HDPE 1%Zn-HZSM-5 3∶1 10∶1 550 550 25.12b acids, aromatics [58] Corn stalk PP 1%Zn-3%Al-MCM-41 1∶1 1∶10 600 600 24.31b aromatic [59] Microcrystalline cellulose powder PP Ni-MCM-41 1∶1 1∶10 650 650 84.6c olefin, aromatics [60] Poplar wood sawdust HDPE (0.5 mol/L)ZSM-5 1∶1 1∶1 500 500 12.72b alkanes, olefins [63] Torrefied poplar wood sawdust HDPE Hierarchical HZSM-5 1∶1 1∶1 550 550 71.75d aromatic [64] Cellulose PP DS-GaMFI 1∶2 1∶15 550 550 52.7b aromatic [65] a: bio-oil yield; b: proportion of aromatics in bio-oil; c: proportion of aromatics and olefins in bio-oil; d: proportion of monocyclic aromatic hydrocarbons in hydrocarbons. -

[1] 洪汉青, 杜玉如, 娄阳, 等. 芳烃生产技术进展及发展趋势[J]. 化学工业,2018,36(5):40−44. doi: 10.3969/j.issn.1673-9647.2018.05.008HONG Hanqing, DU Yuru, LOU Yang, et al. Advances and trends in aromatics technology[J]. Chem Ind,2018,36(5):40−44. doi: 10.3969/j.issn.1673-9647.2018.05.008 [2] LAPINSKI M P, METRO S, PUJADÓ P R, et al. Catalytic Reforming in Petroleum Processing[M]. Handb Petroleum Process, 2015: 229−260. [3] BUSCA G. Production of gasolines and monocyclic aromatic hydrocarbons: From fossil raw materials to green processes[J]. Energies,2021,14(13):4061−4092. doi: 10.3390/en14134061 [4] ZHANG J, YANG J L, ZHANG H F, et al. Research status and future development of biomass liquid fuels[J]. BioResources,2021,16(2):4523−4543. doi: 10.15376/biores.16.2.Zhang [5] ADENIYI O M, AZIMOV U, BURLUKA A. Algae biofuel: Current status and future applications[J]. Renewable Sustainable Energy Rev,2018,90:316−335. doi: 10.1016/j.rser.2018.03.067 [6] XIONG J, ZHANG S, KE L, et al. Research progress on pyrolysis of nitrogen-containing biomass for fuels, materials, and chemicals production[J]. Sci Total Environ,2023,872:162214. doi: 10.1016/j.scitotenv.2023.162214 [7] JAHIRUL M, RASUL M, CHOWDHURY A, et al. Biofuels production through biomass pyrolysis —A technological review[J]. Energies,2012,5(12):4952−5001. doi: 10.3390/en5124952 [8] SHEN X J, ZHANG C F, HAN B X, et al. Catalytic self-transfer hydrogenolysis of lignin with endogenous hydrogen: road to the carbon-neutral future[J]. Chem Soc Rev,2022,51(5):1608−1628. doi: 10.1039/D1CS00908G [9] ZHANG H Y, CHENG Y T, VISPUTE T P, et al. Catalytic conversion of biomass-derived feedstocks into olefins and aromatics with ZSM-5: the hydrogen to carbon effective ratio[J]. Energy Environ Sci,2011,4(6):2297−2307. doi: 10.1039/c1ee01230d [10] 陆强, 郭浩强, 叶小宁, 等. 供氢剂作用下生物质快速热解的研究进展[J]. 林产化学与工业,2017,37(6):1−9.LU Qiang, GUO Haoqiang, YE Xiaoning, et al. Research progress of hydrogen donor assisted fast pyrolysis of biomass[J]. Chem Ind Prod,2017,37(6):1−9. [11] 李致煜, 郭柱, 李显, 等. 生物质“热溶富碳”及其产物利用[J]. 燃料化学学报(中英文),2023,51(2):129−144.LI Zhiyu, GUO Zhu, LI Xian, et al. "Thermal dissolution based carbon enrichment " of biomass waste and the product utilization[J]. J Fuel Chem Technol,2023,51(2):129−144. [12] REN X Y, FENG X B, CAO J P, et al. Catalytic conversion of coal and biomass volatiles: A review[J]. Energy Fuels,2020,34(9):10307−10363. doi: 10.1021/acs.energyfuels.0c01432 [13] ANSARI K B, HASSAN S Z, BHOI R, et al. Co-pyrolysis of biomass and plastic wastes: A review on reactants synergy, catalyst impact, process parameter, hydrocarbon fuel potential, COVID-19[J]. J Environ Chem Eng,2021,9(6):106436−106450. doi: 10.1016/j.jece.2021.106436 [14] FEKHAR B, MISKOLCZI N, BHASKAR T, et al. Co-pyrolysis of biomass and plastic wastes: Investigation of apparent kinetic parameters and stability of pyrolysis oils[J]. EES,2018,154:012022−012029. [15] ENGAMBA ESSO S B, XIONG Z, CHAIWAT W, et al. Review on synergistic effects during co-pyrolysis of biomass and plastic waste: Significance of operating conditions and interaction mechanism[J]. Biomass Bioenergy,2022,159:106415−106438. doi: 10.1016/j.biombioe.2022.106415 [16] UZOEJINWA B B, HE X H, WANG S, et al. Co-pyrolysis of biomass and waste plastics as a thermochemical conversion technology for high-grade biofuel production: Recent progress and future directions elsewhere worldwide[J]. Energy Convers Manage,2018,163:468−492. doi: 10.1016/j.enconman.2018.02.004 [17] 唐紫玥, 陈伟, 陈旭, 等. 微藻与塑料混合热解的热解特性和动力学研究[J]. 燃料化学学报(中英文),2023,51(8):1145−1154.TANG Ziyue, CHEN Wei, CHEN Xu, et al. Pyrolysis characteristics and kinetics of co-pyrolysis of microalgae and plastics[J]. J Fuel Chem Technol,2023,51(8):1145−1154. [18] ZHANG X, LEI H, CHEN S, et al. Catalytic co-pyrolysis of lignocellulosic biomass with polymers: A critical review[J]. Green Chem,2016,18(15):4145−4169. doi: 10.1039/C6GC00911E [19] DORADO C, MULLEN C A, BOATENG A A. Origin of carbon in aromatic and olefin products derived from HZSM-5 catalyzed co-pyrolysis of cellulose and plastics via isotopic labeling[J]. Appl Catal B: Environ,2015,162:338−345. doi: 10.1016/j.apcatb.2014.07.006 [20] 姚佳桂, 刘华财, 黄艳琴, 等. PVC和木质纤维素共热解及Cl释放特性研究[J]. 燃料化学学报(中英文),2023,51(7):939−948.YAO Jiajia, LIU Huacai, HUANG Yanqin, et al. Co-pyrolysis and Cl release characteristics of PVC and lignocellulose[J]. J Fuel Chem Technol,2023,51(7):939−948. [21] 刘世奇, 张素平, 于泰莅, 等. 生物质与塑料共热解协同作用研究[J]. 林产化学与工业,2019,39(3):34−42.LIU Shiqi, ZHANG Suping, YU Taili, et al. Synergistic effect of co-pyrolysis of biomass and plastics[J]. Chem Ind Prod,2019,39(3):34−42. [22] 张东红, 任夏瑾, 蔡红珍, 等. 生物质/塑料共催化热解过程中HZSM-5失活分析[J]. 化工进展,2021,40(8):4259−4267.ZHANG Donghong, REN Xiajin, CAI Hongzhen, et al. Deactivation of HZSM-5 during the catalytic co-pyrolysis of biomass and plastic[J]. Chem Ind Eng Prog,2021,40(8):4259−4267. [23] ÖZSIN G, PÜTÜN A E. A comparative study on co-pyrolysis of lignocellulosic biomass with polyethylene terephthalate, polystyrene, and polyvinyl chloride: Synergistic effects and product characteristics[J]. J Clean Prod,2018,205:1127−1138. doi: 10.1016/j.jclepro.2018.09.134 [24] QI P Y, CHANG G Z, WANG H C, et al. Production of aromatic hydrocarbons by catalytic co-pyrolysis of microalgae and polypropylene using HZSM-5[J]. J Anal Appl Pyrolysis,2018,136:178−185. doi: 10.1016/j.jaap.2018.10.007 [25] CHEN R, ZHANG S, YANG X, et al. Thermal behaviour and kinetic study of co-pyrolysis of microalgae with different plastics[J]. Waste Manage,2021,126:331−339. doi: 10.1016/j.wasman.2021.03.001 [26] YUAN H, FAN H, SHAN R, et al. Study of synergistic effects during co-pyrolysis of cellulose and high-density polyethylene at various ratios[J]. Energy Convers Manage,2018,157:517−526. doi: 10.1016/j.enconman.2017.12.038 [27] RYU H W, KIM D H, JAE J, et al. Recent advances in catalytic co-pyrolysis of biomass and plastic waste for the production of petroleum-like hydrocarbons[J]. Bioresour Technol,2020,310:123473−123480. doi: 10.1016/j.biortech.2020.123473 [28] JIN W, SHEN D, LIU Q, et al. Evaluation of the co-pyrolysis of lignin with plastic polymers by TG-FTIR and Py-GC/MS[J]. Polym Degrad Stab,2016,133:65−74. doi: 10.1016/j.polymdegradstab.2016.08.001 [29] ZHENG Y, TAO L, YANG X, et al. Study of the thermal behavior, kinetics, and product characterization of biomass and low-density polyethylene co-pyrolysis by thermogravimetric analysis and pyrolysis-GC/MS[J]. J Anal Appl Pyrolysis,2018,133:185−197. doi: 10.1016/j.jaap.2018.04.001 [30] CHEN R J, ZHANG S Y, CONG K L, et al. Insight into synergistic effects of biomass-polypropylene co-pyrolysis using representative biomass constituents[J]. Bioresour Technol,2020,307:123243−123250. doi: 10.1016/j.biortech.2020.123243 [31] SHAFAGHAT H, LEE H W, YANG L, et al. Catalytic co-conversion of Kraft lignin and linear low-density polyethylene over mesoZSM-5 and Al-SBA-15 catalysts[J]. Catal Today,2020,355:246−251. doi: 10.1016/j.cattod.2019.04.052 [32] BU Q, CHEN K, XIE W, et al. Hydrocarbon rich bio-oil production, thermal behavior analysis and kinetic study of microwave-assisted co-pyrolysis of microwave-torrefied lignin with low density polyethylene[J]. Bioresour Technol,2019,291:121860−121865. doi: 10.1016/j.biortech.2019.121860 [33] JOHANSSON A-C, SANDSTRÖM L, ÖHRMAN O G W, et al. Co-pyrolysis of woody biomass and plastic waste in both analytical and pilot scale[J]. J Anal Appl Pyrolysis,2018,134:102−113. doi: 10.1016/j.jaap.2018.05.015 [34] ZHANG H, LIKUN P K W, XIAO R. Improving the hydrocarbon production via co-pyrolysis of bagasse with bio-plastic and dual-catalysts layout[J]. Sci Total Environ,2018,618:151−156. doi: 10.1016/j.scitotenv.2017.11.045 [35] DHANALAKSHMI C S, AHALYA N, VIDHYALAKSHMI P, et al. Individual and catalytic co-pyrolysis of agricultural outcomes and polymeric materials over nano-HZSM-5 zeolite: Synergistic effects and yield analysis for heating applications[J]. J Nanomater,2022,2022:3743299−3743310. [36] PARK Y-K, LEE B, LEE H W, et al. Co-feeding effect of waste plastic films on the catalytic pyrolysis of Quercus variabilis over microporous HZSM-5 and HY catalysts[J]. Chem Eng J,2019,378:122151−122157. doi: 10.1016/j.cej.2019.122151 [37] 郑云武, 王继大, 刘灿, 等. 改性HZSM-5催化生物质与塑料热解制备芳烃和生物炭[J]. 农业工程学报,2020,36(17):190−201. doi: 10.11975/j.issn.1002-6819.2020.17.023ZHENG Yunwu, WANG Jida, LIU Can, et al. Preparation of aromatic and bio-char by pyrolysis of biomass and plastics catalyzed by modified HZSM-5[J]. Trans Chin Soc Agric Eng,2020,36(17):190−201. doi: 10.11975/j.issn.1002-6819.2020.17.023 [38] BHOI P R, OUEDRAOGO A S, SOLOIU V, et al. Recent advances on catalysts for improving hydrocarbon compounds in bio-oil of biomass catalytic pyrolysis[J]. Renewable Sustainable Energy Rev,2020,121:109676−109688. doi: 10.1016/j.rser.2019.109676 [39] KALOGIANNIS K G, STEFANIDIS S D, KARAKOULIA S A, et al. First pilot scale study of basic vs acidic catalysts in biomass pyrolysis: Deoxygenation mechanisms and catalyst deactivation[J]. Appl Catal B: Environ,2018,238:346−357. doi: 10.1016/j.apcatb.2018.07.016 [40] LIN X, KONG L, CAI H, et al. Effects of alkali and alkaline earth metals on the co-pyrolysis of cellulose and high density polyethylene using TGA and Py-GC/MS[J]. Fuel Process Technol,2019,191:71−78. doi: 10.1016/j.fuproc.2019.03.015 [41] WENG J, CUI C, ZHOU Z, et al. Online investigation on catalytic co-pyrolysis of cellulose and polyethylene over magnesium oxide by advanced mass spectrometry[J]. Bioresour Technol,2021,338:125560−125566. doi: 10.1016/j.biortech.2021.125560 [42] SOPHONRAT N, SANDSTRÖM L, SVANBERG R, et al. Ex situ catalytic pyrolysis of a mixture of polyvinyl chloride and cellulose using calcium oxide for HCl adsorption and catalytic reforming of the pyrolysis products[J]. Ind Eng Chem Res,2019,58(31):13960−13970. doi: 10.1021/acs.iecr.9b02299 [43] 王志伟, 郭帅华, 吴梦鸽, 等. 生物质与塑料催化共热解技术研究进展[J]. 化工进展,2022,42(5):1−13.WANG Zhiwei, GUO Shuaihua, WU Mengge, et al. Recent advances on catalytic co-pyrolysis of biomass and plastic[J]. Chem Ind Eng Prog,2022,42(5):1−13. [44] LIN X N, ZHANG Z F, ZHANG Z J, et al. Catalytic fast pyrolysis of a wood-plastic composite with metal oxides as catalysts[J]. Waste Manage,2018,79:38−47. doi: 10.1016/j.wasman.2018.07.021 [45] WANG Z, SHEN D, WU C, et al. Thermal behavior and kinetics of co-pyrolysis of cellulose and polyethylene with the addition of transition metals[J]. Energy Convers Manage,2018,172:32−38. doi: 10.1016/j.enconman.2018.07.010 [46] WANG Z, LIU G, SHEN D, et al. Co-pyrolysis of lignin and polyethylene with the addition of transition metals - Part I: Thermal behavior and kinetics analysis[J]. J Energy Inst,2020,93(1):281−291. doi: 10.1016/j.joei.2019.03.003 [47] 张冬炎. 改性ZSM-5分子筛催化2-甲基呋喃甲醇耦合反应制轻质芳烃的基础研究[D]. 南京: 南京理工大学, 2019.ZHANG Dongyan. Basic study of light aromatics production from 2-methylfuran with methanol over modified ZSM-5 zeolite[D]. Nanjing: Nanjing University of Science and Technology, 2019. [48] 李承宇, 张军, 袁浩然, 等. 纤维素热解转化的研究进展[J]. 燃料化学学报,2021,49(12):1733−1751. doi: 10.1016/S1872-5813(21)60134-2LI Chengyu, ZHANG Jun, YUAN Haoran, et al. Advance on the pyrolytic transformation of cellulose[J]. J Fuel Chem Technol,2021,49(12):1733−1751. doi: 10.1016/S1872-5813(21)60134-2 [49] JAE J, TOMPSETT G A, FOSTER A J, et al. Investigation into the shape selectivity of zeolite catalysts for biomass conversion[J]. J Catal,2011,279(2):257−268. doi: 10.1016/j.jcat.2011.01.019 [50] ZHANG X, YU Z, LU X, et al. Catalytic co-pyrolysis of microwave pretreated chili straw and polypropylene to produce hydrocarbons-rich bio-oil[J]. Bioresour Technol,2021,319:124191−124198. doi: 10.1016/j.biortech.2020.124191 [51] ZHAO Y, YANG X, FU Z, et al. Synergistic effect of catalytic co-pyrolysis of cellulose and polyethylene over HZSM-5[J]. J Therm Anal Calorim,2019,140(1):363−371. [52] LI X, ZHANG H, LI J, et al. Improving the aromatic production in catalytic fast pyrolysis of cellulose by co-feeding low-density polyethylene[J]. Appl Catal A: Gen,2013,455:114−121. doi: 10.1016/j.apcata.2013.01.038 [53] ZHANG X, LEI H, ZHU L, et al. Thermal behavior and kinetic study for catalytic co-pyrolysis of biomass with plastics[J]. Bioresour Technol,2016,220:233−238. doi: 10.1016/j.biortech.2016.08.068 [54] SEBESTYéN Z, BLAZSó M, JAKAB E, et al. Thermo-catalytic studies on a mixture of plastic waste and biomass[J]. J Therm Anal Calorim,2021,147(11):6259−6270. [55] PARK Y-K, SIDDIQUI M Z, KANG Y, et al. Increased aromatics formation by the use of high-density polyethylene on the catalytic pyrolysis of mandarin peel over HY and HZSM-5[J]. Catal,2018,8(12):656−669. [56] LIN X, ZHANG Z, WANG Q. Evaluation of zeolite catalysts on product distribution and synergy during wood-plastic composite catalytic pyrolysis[J]. Energy,2019,189:116174−116183. doi: 10.1016/j.energy.2019.116174 [57] ZHENG Y, WANG J, LIU C, et al. Catalytic copyrolysis of metal impregnated biomass and plastic with Ni-based HZSM-5 catalyst: Synergistic effects, kinetics and product distribution[J]. Energy Res,2020,44:5917−5935. doi: 10.1002/er.5370 [58] NANDAKUMAR T, DWIVEDI U, PANT K K, et al. Wheat straw/HDPE co-reaction synergy and enriched production of aromatics and light olefins via catalytic co-pyrolysis over Mn, Ni, and Zn metal modified HZSM-5[J]. Catal Today,2023,408:111−126. doi: 10.1016/j.cattod.2022.07.019 [59] SUN T L, LEI T Z, LI Z F, et al. Catalytic co-pyrolysis of corn stalk and polypropylene over Zn-Al modified MCM-41 catalysts for aromatic hydrocarbon-rich oil production[J]. Ind Crop Prod,2021,171:113843−113855. doi: 10.1016/j.indcrop.2021.113843 [60] SHI Y, LIU C, ZHUO J, et al. Investigation of a Ni-modified MCM-41 catalyst for the reduction of oxygenates and carbon deposits during the co-pyrolysis of cellulose and polypropylene[J]. ACS Omega,2020,5(32):20299−20310. doi: 10.1021/acsomega.0c02205 [61] AHMED M H M, BATALHA N, MAHMUDUL H M D, et al. A review on advanced catalytic co-pyrolysis of biomass and hydrogen-rich feedstock: Insights into synergistic effect, catalyst development and reaction mechanism[J]. Bioresour Technol,2020,310:123457−123471. doi: 10.1016/j.biortech.2020.123457 [62] 朱亮, 黄明, 丁紫霞, 等. 烘焙脱氧毛竹与高密度聚乙烯共催化热解制备轻质芳烃[J]. 燃料化学学报,2022,50(8):993−1003.ZHU Liang, HUANG Ming, DING Zixia, et al. Production of light bio-aromatics from co-catalytic fast pyrolysis of torrefied bamboo and high-density polyethylene[J]. J Fuel Chem Technol,2022,50(8):993−1003. [63] SARKER M, LIU R, RAHMAN M M, et al. Impact of acid-modified ZSM-5 on hydrocarbon yield of catalytic co-pyrolysis of poplar wood sawdust and high-density polyethylene by Py-GC/MS analysis[J]. J Energy Inst,2020,93(6):2435−2443. doi: 10.1016/j.joei.2020.08.001 [64] LIN X N, KONG L S, REN X J, et al. Catalytic co-pyrolysis of torrefied poplar wood and high-density polyethylene over hierarchical HZSM-5 for mono-aromatics production[J]. Renewable Energy,2021,164:87−95. doi: 10.1016/j.renene.2020.09.071 [65] LI X, PANG Y, DING Z, et al. Enhancing the synergistic effect of cellulose and polypropylene for petrochemical production during catalytic fast pyrolysis by mesoporous gallium-MFI zeolites[J]. Energy Fuels,2021,35(23):19525−19534. doi: 10.1021/acs.energyfuels.1c02627 [66] QIAN M, LEI H, VILLOTA E, et al. Enhanced production of renewable aromatic hydrocarbons for jet-fuel from softwood biomass and plastic waste using hierarchical ZSM-5 modified with lignin-assisted re-assembly[J]. Energy Convers Manage,2021,236:114020−114029. doi: 10.1016/j.enconman.2021.114020 [67] ZHOU Z, CHEN X, WANG Y, et al. Online photoionization mass spectrometric evaluation of catalytic co-pyrolysis of cellulose and polyethylene over HZSM-5[J]. Bioresour Technol,2019,275:130−137. doi: 10.1016/j.biortech.2018.12.045 [68] CHENG Y T, HUBER G W. Production of targeted aromatics by using Diels-Alder classes of reactions with furans and olefins over ZSM-5[J]. Green Chem,2012,14(11):3114−3125. doi: 10.1039/c2gc35767d [69] HASSAN H, LIM J K, HAMEED B H. Recent progress on biomass co-pyrolysis conversion into high-quality bio-oil[J]. Bioresour Technol,2016,221:645−655. doi: 10.1016/j.biortech.2016.09.026 [70] 惠贺龙, 李松庚, 宋文立. 生物质与废塑料催化热解制芳烃(Ⅰ): 协同作用的强化[J]. 化工学报,2020,48(3):286−292.HUI Helong, LI Songgeng, SONG Wenli. Aromatic hydrocarbon from catalytic pyrolysis of biomass and plastic wastes (Ⅰ): Enhancing synergistic effect[J]. J Chem Eng,2020,48(3):286−292. [71] DING K, ZHONG Z P, WANG J, et al. Improving hydrocarbon yield from catalytic fast co-pyrolysis of hemicellulose and plastic in the dual-catalyst bed of CaO and HZSM-5[J]. Bioresour Technol,2018,261:86−92. doi: 10.1016/j.biortech.2018.03.138 [72] VO T A, LY H V, TRAN Q K, et al. Lumped-kinetic modeling and experiments on co-pyrolysis of palm kernel cake with polystyrene using a closed-tubing reactor to upgrade pyrolysis products[J]. Energy Convers Manage,2021,249:114879−114895. doi: 10.1016/j.enconman.2021.114879 [73] DING K, HE A, ZHONG D X, et al. Improving hydrocarbon yield via catalytic fast co-pyrolysis of biomass and plastic over ceria and HZSM-5: An analytical pyrolyzer analysis[J]. Bioresour Technol,2018,268:1−8. doi: 10.1016/j.biortech.2018.07.108 [74] WENG J, CHENG Z, ZHANG Y, et al. Online evaluation of catalytic co-pyrolysis of hemicellulose and polypropylene over CaO catalyst[J]. Fuel,2023,332:125993−126000. doi: 10.1016/j.fuel.2022.125993 -

下载:

下载: