Comparative study on the performance of n-dodecane isomerization reaction on molecular sieve catalysts with different topological structures

-

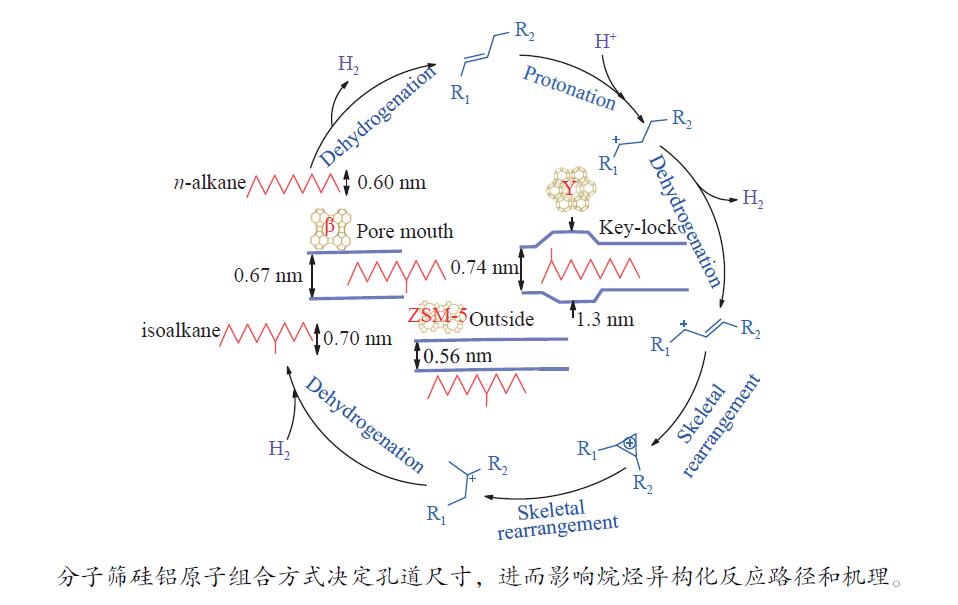

摘要: 采用硅铝比相近的Y分子筛、ZSM-5分子筛和β分子筛分别负载贵金属约0.5% Pt 制备催化剂,通过XRD、XRF、TEM、N2物理吸附-脱附、NH3-TPD、Py-FTIR、27Al核磁等手段研究了不同拓扑结构分子筛晶体结构、元素组成、孔结构、酸性以及Al分布的差异,进而考察了拓扑结构对催化剂催化正十二烷异构化反应性能的影响。结果表明,当硅铝比接近时,ZSM-5分子筛总酸量及骨架铝比例最高、平均孔径最小,Y分子筛总酸量及骨架铝比例最低、平均孔径最大,而β分子筛的总酸量、骨架铝比例以及平均孔径介于两者之间,说明不同拓扑结构分子筛硅铝原子组合方式不同,不仅影响孔道结构和孔口尺寸,而且会因为铝所处位置的不同而影响酸性;在正十二烷异构化反应中,Pt/ZSM-5催化剂活性最高且主要发生的是外表面无选择性反应,Pt/Y催化剂活性最低且异构化反应主要在孔道内,而Pt/β催化剂活性介于两者之间,异构化反应发生于孔口处以锁匙反应为主。Abstract: The catalysts were prepared by loading about 0.5% Pt noble metal on Y molecular sieves, ZSM-5 molecular sieves and β molecular sieves with similar Si/Al ratios. The crystal structures of the molecular sieves with different topologies, elemental compositions, pore structures, activities, and Al distributions were investigated by means of XRD, XRF, TEM, N2 physical adsorption and desorption, NH3-TPD, Py-FTIR, and 27Al NMR. And then the effect of topology on the catalytic performance of n-dodecane isomerization reaction was investigated. The results showed that when the Si/Al ratios were close to each other, the ZSM-5 molecular sieve had the highest total acid and skeleton Al ratio and the smallest average pore size, the Y molecular sieve had the lowest total acid and skeleton Al ratio and the largest average pore size, and the β molecular sieve's total acid, skeleton Al ratio, and average pore size were between the two others, which indicated that different topologies of the molecular sieves with different combinations of Si/Al atoms affected not only the structure of the pores and the size of the pore but also the number of acidity. In the n-dodecane isomerization reaction, the Pt/ZSM-5 catalyst had the highest activity and the main reaction occurred on the outer surface without selectivity, the Pt/Y catalyst had the lowest activity and the isomerization reaction mainly occurred inside the pores, while the Pt/β catalyst had the activity between the other two catalysts and the isomerization reaction occurred dominantly at the pore opening as the key-locking reaction.

-

Key words:

- similar Si/Al ratio /

- β-molecular sieve /

- Y-molecular sieve /

- ZSM-5 molecular sieve /

- topological /

- isomerization

-

表 1 Pt/β、Pt/Y、Pt/ZSM-5三种催化剂的主要组成

Table 1 Main components of Pt/β, Pt/Y and Pt/ZSM-5 catalysts

Catalyst SiO2 /% Al2O3 /% nSiO2/nAl2O3 Pt /% Pt/β 94.90 4.60 35.1 0.50 Pt/Y 94.80 4.71 34.2 0.49 Pt/ZSM-5 95.05 4.46 36.2 0.49 表 2 Pt/β、Pt/Y、Pt/ZSM-5的孔结构参数

Table 2 Pore structure parameters of Pt/β, Pt/Y, Pt/ZSM-5

Sample SBET / (m2·g−1) Smicro / (m2·g−1) Smeso / (m2·g−1) vmicro / (cm3·g−1) vmeso / (cm3·g−1) Average pore diameter / nm Pt/β 613 567 46 0.43 0.20 4.11 Pt/Y 627 565 61 0.43 0.22 4.15 Pt/ZSM-5 332 322 10 0.18 0.03 2.53 表 3 Pt/β、Pt/Y、Pt/ZSM-5的酸分布

Table 3 Acid distribution parameter of Pt/β, Pt/Y, Pt/ZSM-5

Sample Weak /

(cm3·g−1)Weak /% Medium /

(cm3·g−1)Medium /% Strong /

(cm3·g−1)Strong /% Total Pt/β 4.53 33.9 8.48 63.4 0.36 2.7 13.37 Pt/Y 0.41 33.3 0.73 59.7 0.09 7.0 1.23 Pt/ZSM-5 9.19 44.4 6.39 30.9 5.11 24.7 20.69 -

[1] MISRA P, ALVAREZ-MAJMUTOV A, CHEN J. Isomerization catalysts and technologies for biorefining: Opportunities for producing sustainable aviation fuels[J]. Fuel,2023,351:128994. doi: 10.1016/j.fuel.2023.128994 [2] SCHMIDT J E, SMIT B, CHEN C Y, XIE D, MAESEN T L. Toward superior hydroisomerization catalysts through thermodynamic optimization[J]. ACS Catal.,2023,13(10):6710−6720. doi: 10.1021/acscatal.3c00391 [3] CHEN T, GU C, OUYANG Y, ZHUANG L, YAO Z, ZOU K, WANG Y, LUO Y, SHU X. Synthesis of high hydrothermal stability Beta zeolite with crosslinked starch and catalytic performance in catalytic cracking reaction[J]. Fuel,2022,318:123696.1−123696.12. [4] LI X, YANG X, WANG Q, LI S, YE Y, WANG D, ZHENG Z. Synthesis of Pt-based TS-1 catalysts for selective hydrogenation to produce C15–C18 alkanes from the FAME: Effect of rare-earth metal additives[J]. J Clean Prod,2022,350:131520. doi: 10.1016/j.jclepro.2022.131520 [5] WANG Y, LIU W, ZHANG W, SUN J H, LI R F. Comparison of n-dodecane hydroisomerization performance over Pt supported ZSM-48 and ZSM-22[J]. Catal Lett, 2021, 151(12): 3492−3500. [6] 王琰, 刘伟, 李赛, 孙景辉, 张巍, 向江南, 范彬彬, 李瑞丰. Pt 负载位置对双功能催化剂正十二烷加氢异构化性能影响[J]. 石油学报 (石油加工),2021,37(6):1338.WANG Yan, LIU Wei, LI Sai, SUN Jing-hui, ZHANG Wei, XAING jiang-nan, FAN bin-bin, LI rui-feng. Influence of Pt Position on the Performance of Bifunctional Catalysts for n-Dodecane Hydroisomerization[J]. Acta Pet Sin (Pet Process Sect),2021,37(6):1338. [7] CHEN Y, LI C, CHEN X, LIANG C. Synthesis of ZSM-23 zeolite with dual structure directing agents for hydroisomerization of n-hexadecane[J]. Microporous Mesoporous Mater,2018,268:216−224. doi: 10.1016/j.micromeso.2018.04.033 [8] ZHANG C, WANG H, YU X, PENG C, ZHANG A, LIANG X, YAN Y. Correlation between the molecular structure and viscosity index of CTL base oils based on ridge regression[J]. ACS omega,2022,7(22):18887−18896. doi: 10.1021/acsomega.2c01877 [9] DEMBICKI H. Practical Petroleum Geochemistry for Exploration and Production[M]. Amsterdam: Elsevier, 2022. [10] DING Y, MIAO D, FENG. Enhanced formation of multi-branched isoparaffins in syngas conversion by ZnCrOx-MCM-22 composites[J]. Appl Catal B: Environ,2022,316:121628. doi: 10.1016/j.apcatb.2022.121628 [11] HIRSHFELD D S, KOLB J A, ANDERSON J E, IQBAL A, SUTHERLAND I. Refining economics of higher octane sensitivity, research octane number and ethanol content for U. S. gasoline[J]. Energy Fuels, 2021, 35(18): 14816−14827. [12] CLAUDE M C, MARTENS J A. Monomethyl-branching of long n-alkanes in the range from decane to tetracosane on Pt/H-ZSM-22 bifunctionalcatalyst[J]. J Catal,2000,190(1):39−48. doi: 10.1006/jcat.1999.2714 [13] GUO K, MA A Z, LI J Z. Research Progress of n-heptane isomerization reaction[J]. Acta Pet Sin (Pet Process Sect),2023,39(1):213. [14] GOURSOT A, BERTHOMIEU D. Calculations of nuclear magnetic resonance parameters in zeolites[J]. ChemInform, 2005, 36(11): 449−460. [15] VU X, ARMBRUSTER U, MARTIN A. Micro/mesoporous zeolitic composites: Recent developments in synthesis and catalytic applications[J]. Catalysts,2016,6(12):183. doi: 10.3390/catal6120183 [16] ALHARTHI A I. Pd Supported on ZSM-5 with different ratios of Si/Al as catalysts for direct catalytic decomposition of methane[J]. J Taibah Univ Sci,2021,15(1):567−573. doi: 10.1080/16583655.2021.1978810 [17] RAHMAN M, INFANTES-MOLINA A, HOFFMAN A S, BARE S R, KHATIB S J. Effect of Si/Al ratio of ZSM-5 support on structure and activity of Mo species in methane dehydroaromatization[J]. Fuel,2020,278:118290. doi: 10.1016/j.fuel.2020.118290 [18] HOU Y, LI X, SUN M, LI C, XIAO Y, MING H, LI C, BAKHTIAR S H, LEI K, YU S, WANG Z, HU Z, CHEN L, SU B. The effect of hierarchical single-crystal ZSM-5 zeolites with different Si/Al ratios on its pore structure and catalytic performance[J]. Front Chem Sci Eng,2021,15:269−278. doi: 10.1007/s11705-020-1948-3 [19] ZHANG X, GUO Q, QIN B, ZHANG Z, LING F, SUN W, LI R. Structural features of binary microporous zeolite composite Y-Beta and its hydrocracking performance[J]. Catal Today,2010,149(1/2):212−217. doi: 10.1016/j.cattod.2009.11.005 [20] 曾鹏晖, 张莉莉, 郭小忠, 李明富, 郭巧霞, 牛超, 申宝剑. 不同硅铝比Al-ITQ-13分子筛的甲醇制丙烯反应催化性能[J]. 燃料化学学报,2017,45(11):1349−1355. doi: 10.1016/S1872-5813(17)30059-2ZENG Peng-hui, ZHANG Li-li, GUO Xiao-zhong, LI Ming-fu, GUO Qiao-xia, NIU Chao, SHEN Bao-jian. Catalytic performances of Al-ITQ-13 zeolites with different SiO2/Al2O3 ratios in the conversion of methanol to propene[J]. J Fuel Chem Technol,2017,45(11):1349−1355. doi: 10.1016/S1872-5813(17)30059-2 [21] ABBOT J. Active sites and intermediates for isomerization and cracking of cyclohexane on HY[J]. J Catal,1990,123(2):383−395. doi: 10.1016/0021-9517(90)90137-9 [22] DING L, ZHENG Y, ZHANG Z, RING Z, CHEN J. Hydrotreating of light cycled oil using WNi/Al2O3 catalysts containing zeolite beta and/or chemically treated zeolite Y[J]. J Catal,2006,241(2):435−445. doi: 10.1016/j.jcat.2006.05.004 [23] 杨洋, 孙娜, 王雪, 王钰佳, 王海彦. 梯度孔Hβ的制备及其催化苯加氢烷基化性能[J]. 辽宁石油化工大学学报,2022,42(1):7−12. doi: 10.3969/j.issn.1672-6952.2022.01.002YANG Yang, SUN Na, WANG Xue, WANG Yu-jia, WANG Hai-yan. Preparation of hierarchical porous Hβ and its catalytic performance in benzene hydroalkylation[J]. J Liaoning Pet Univ,2022,42(1):7−12. doi: 10.3969/j.issn.1672-6952.2022.01.002 [24] 金丛, 沈健. U S Y分子筛催化噻吩十二烯烷基化工艺条件的考察[J]. 辽宁石油化工大学学报,2014,34(2):29−32. doi: 10.3969/j.issn.1672-6952.2014.02.008JIN Cong, SHEN Jian. Processing conditions of alkylation of thiophene with laurylene over USY zeolite[J]. J Liaoning Pet Univ,2014,34(2):29−32. doi: 10.3969/j.issn.1672-6952.2014.02.008 [25] 盛路阳, 展俊岭, 张旭鹏, 吴邦昊, 张钰, 张吉波. 核壳型ZSM-5@Beta分子筛的制备及催化烷基化合成2, 6-二甲基萘[J]. 燃料化学学报,2022,50(9):1202−1210. doi: 10.1016/S1872-5813(22)60014-8SHENG Lu-yang, ZHAN Jun-ling, ZHANG Xu-peng, WU Bang-hao, ZHANG Yu, ZHANG Ji-bo. Preparation of core-shell ZSM-5@Beta molecular sieve and catalytic alkylation to 2, 6-dimethylnaphthalene[J]. J Fuel Chem Technol,2022,50(9):1202−1210. doi: 10.1016/S1872-5813(22)60014-8 [26] NEWSAM J M, TREACY M M J, KOETSIER W T, GRUYTER C B D. Structural characterization of zeolite beta[J]. Proc R Soc Lond A,1988,420(1859):375−405. doi: 10.1098/rspa.1988.0131 [27] BERGERHOFF G, BAUR W H, NOWACKI W. Über die kristallstrukturen des faujasits[J]. N Jb Miner Mh,1958,1958:193−200. [28] KOKOTAILO G T, LAWTON S L, OLSON D H, MEIER W M. Structure of synthetic zeolite ZSM-5[J]. Nature,1978,272(5652):437−438. doi: 10.1038/272437a0 [29] EAPEN M J, REDDY K S N, SHIRALKAR V P. Hydrothermal crystallization of zeolite beta using tetraethylammonium bromide[J]. Zeolites,1994,14(4):295−302. doi: 10.1016/0144-2449(94)90099-X [30] OLEKSIAK M D, MURAOKA K, HSIEH M F, CONATO MT, SHIMOJIMA A, OKUBO T, CHAIKITTISILP W, RIMER J D. Organic-free synthesis of a highly siliceous faujasite zeolite with spatially biased Q4 (nAl) Si speciation[J]. Ang Chem Int Ed,2017,129(43):13551−13556. doi: 10.1002/ange.201702672 [31] LIU X M, FENG Y Z. Optimization of nanopores and acidity of USY zeolite by citric modification[J]. Catal Today,2001,68(1/3):145−154. doi: 10.1016/S0920-5861(01)00275-9 [32] SANG S, CHANG F, LIU Z, HE C, HE Y, XU L. Difference of ZSM-5 zeolites synthesized with various templates[J]. Catal Today,2004,93:729−734. [33] 李云赫, 洪新, 高畅, 牛晓青, 唐克. 杂原子介孔MCM-41分子筛的制备及其对含喹啉模拟柴油的吸附脱氮性能[J]. 燃料化学学报(中英文),2019,47(10):1195−1204.LI Yun-he, HONG Xin, GAO Chang, NIU Xiao-qing, TANG Ke. Preparation of heteroatom-containing mesoporous MCM-41 molecular sieves and their performance in the adsorption denitrification of quinoline in model diesel oil[J]. J Fuel Chem Technol,2019,47(10):1195−1204. [34] 李懿, 刘宁, 张润铎, 李英霞. NO与NH3在不同构型分子筛催化剂中吸附和扩散的分子模拟[J]. 工业催化, 2016, 24(10): 33−40.LI Yi, LIU Ning, ZHANG Run-duo, LI Ying-xia. Molecular simulations of adsorption and diffusion of NO and NH3 over zeolite catalysts with various structure configurations[J]. Ind Catal, 2016, 24(10): 33−40. [35] BARZETTI T, SELLI E, MOSCOTTI D, FORNI L. Pyridine and ammonia as probes for FTIR analysis of solid acid catalysts[J]. J Chem Soc, Faraday Trans,1996,92:1401−1407. doi: 10.1039/ft9969201401 [36] MARTENS J A , VERBOEKEND D , THOMAS K , VANBUTSELE G, GILSON J, PÉREZ-RAMÍREZ J. Hydroisomerization of emerging renewable hydrocarbons using hierarchical Pt/H-ZSM-22 catalyst[J]. ChemSusChem,2013,6(3):421−425. [37] HAN Y, YUAN J, XING M, CAO J, CHEN Z, ZHANG L, TAO Z, LIU Z, ZHENG S, WEN X, YANG Y, LI Y. Shape selectivity of zeolite for hydroisomerization of long-chain alkanes[J]. New J Chem,2023,47(3):1401−1412. doi: 10.1039/D2NJ04976G -

下载:

下载: