Effect of NiW/SAPO-11 catalyst on hydroisomerization performance of model compound eicosane for tail oil hydrogenation of coal tar

-

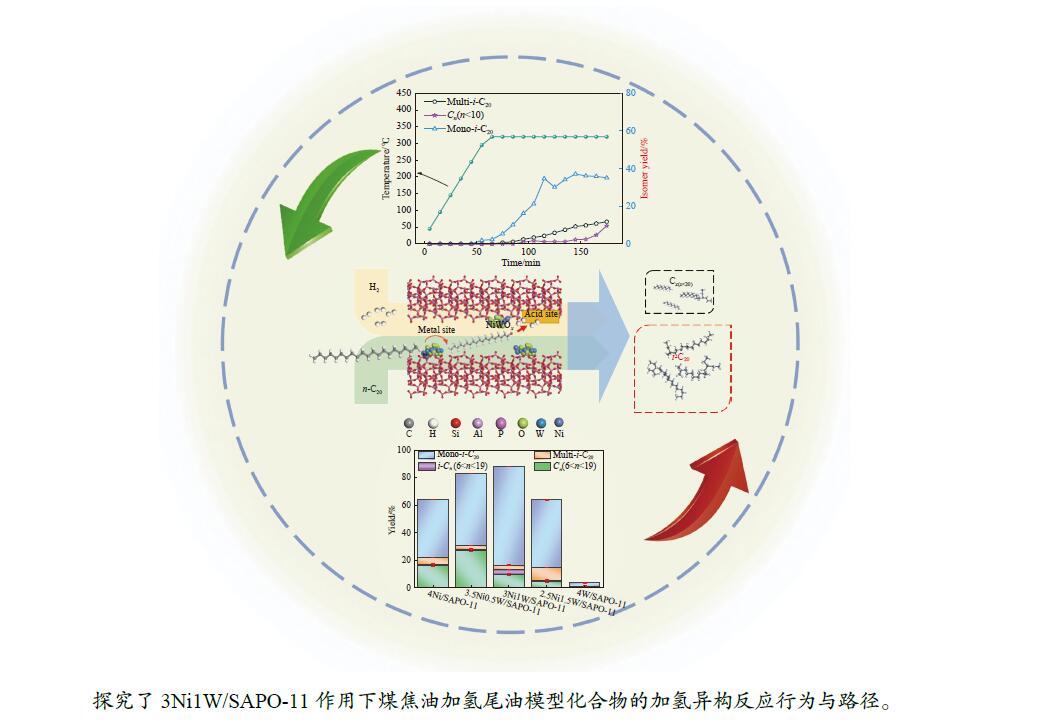

摘要: 以SAPO-11分子筛为载体,采用机械化学法制备Ni系催化剂,引入W调节其电子结构、晶粒尺寸与形态分布以及催化剂的孔结构、酸性与酸量等,基于对XRD、TEM、BET、NH3-TPD、吡啶吸附红外等结果的深入分析,探究催化剂NiW配比对催化剂性质和煤焦油加氢尾油模型化合物正二十烷(n-C20)加氢异构性能的影响规律。结果表明,Ni/SAPO-11负载W后,比表面积不同程度增加,W质量分数为0.5%时比表面积达到最大值149 m2/g;Ni的平均粒径减小,W质量分数为1%时降至最小值4.43 nm,比Ni/SAPO-11减小36%,且Ni0的含量和表面酸量均最高。此外,W促进了Ni的还原,使得还原峰温向低温方向移动。XPS分析表明,随着W含量的增加,Ni0的结合能降低,W5+的结合能升高。二十烷(n-C20)的加氢异构产物分布显示,3Ni1W/SAPO-11作用下n-C20的转化率和异二十烷(i-C20)的收率均最高,分别为88.23%和75.72%,且以单支链异二十烷(Mono-i-C20)为主,收率达71.65%。在线取样结果显示,n-C20在金属位点与酸功能的双重作用下先生成单支链异构体,随着反应的进行向多支链异构体转化,不稳定的多支链异构体会进一步裂解成小分子烷烃。Abstract: Ni-based catalysts were prepared by mechanochemical method with SAPO-11 zeolite as the carrier, and W was introduced to adjust the electronic structure, grain size and morphology of Ni particle, as well as pore structure, acidity, and acid amount of the catalyst. The effect of NiW ratios on catalyst properties and the hydro-isomerization properties of n-eicosane (n-C20), which is a model compound for coal tar hydrogenation tail oil, was explored by XRD, TEM, BET, NH3-TPD and Py-FTIR. The results show that the specific surface area of Ni/SAPO-11 increases with the addition of W, and reaches the maximum value of 149 m2/g at the W addition of 0.5%. The average particle size of Ni decreases with the addition of W, and reaches to the minimum value of 4.43 nm at the W addition of 1%, which is 36% less than that of Ni/SAPO-11. At this time, the content of Ni0 and the amount of surface acid are the highest. In addition, W promotes the reduction of Ni, causing the reduction peak temperature to move toward lower temperature. XPS results show that with the increase of W content, the binding energy of Ni0 decreases while that of W5+ increases. The isomers distribution of eicosane (n-C20) shows that the conversion of n-C20 and the yield of i-C20 are the highest in the presence of 3Ni1W/SAPO-11, which are 88.23% and 75.72%, respectively. It is mainly the mono-i-C20 with a yield of 71.65%. The on-line sampling results show that n-C20 generates the mono-branched isomer under the action of metal site and acid function. With the reaction, the mono-branched isomer is transformed into the multi-branched isomer, and the unstable multi-branched isomer is cracked into small molecule alkanes.

-

Key words:

- SAPO-11 /

- long-chain alkanes /

- NiW catalysts /

- hydro-isomerization

-

表 1 催化剂的孔结构参数和相对结晶度

Table 1 Pore structure parameters and relative crystallinity of catalysts

Sample SBETa/(m2·g−1) Smicb/(m2·g−1) Sextc/(m2·g−1) d/nm v/(cm3·g−1) Cd/% SAPO-11 184 131 53 6.52 0.30 100 4Ni/SAPO-11 111 58 53 8.32 0.23 84.93 3.5Ni0.5W/SAPO-11 149 109 40 3.49 0.13 85.80 3Ni1W/SAPO-11 123 75 48 4.91 0.15 88.39 2.5Ni1.5W/SAPO-11 113 67 46 5.17 0.15 86.83 4W/SAPO-11 134 77 57 7.76 0.26 89.28 a: BET method; b: t-plot method; c: Sext was calculated by subtracting micropore area from BET area; d: The relative crystallinity derived from XRD analysis using the ratio of the sum of zeolite peaks to background with the parent SAPO-11 as reference. 表 2 催化剂的酸性分布

Table 2 Acid site distribution of catalysts

Sample Weak acidity/(mmol·g−1) Medium strong acidity/(mmol·g−1) Total/(mmol·g−1) SAPO-11 0.33 0.55 0.88 4Ni/SAPO-11 0.19 0.38 0.57 3.5Ni0.5W/SAPO-11 0.28 0.41 0.69 3Ni1W/SAPO-11 0.30 0.45 0.75 2.5Ni1.5W/SAPO-11 0.29 0.40 0.69 4W/SAPO-11 0.25 0.36 0.61 表 3 催化剂的理化性质

Table 3 Physicochemical properties of the catalysts

Sample Acidity/(μmol·g−1) dNi/nm DNia/% CNib/(μmol·g−1) CNi/CB CB CL SAPO-11 47.28 139.03 − − − − 4Ni/SAPO-11 14.02 58.03 6.96 13.95 95.08 6.78 3.5Ni0.5W/SAPO-11 30.89 35.23 5.78 16.80 100.17 3.24 3Ni1W/SAPO-11 35.30 39.37 4.43 21.92 112.03 3.17 2.5Ni1.5W/SAPO-11 34.25 42.43 4.85 20.02 93.36 2.72 4W/SAPO-11 41.34 125.81 − − − − a: Ni dispersion (dispersion (%)=97.1/dNi); b: Calculated from the metal content and metal dispersity of Ni. 表 4 不同催化剂在类似反应条件下的催化性能

Table 4 The catalytic performance of different catalysts under similar reaction conditions

-

[1] NIU M, SONG Z, PAN L, et al. Combined process of hydrocracking and hydrofining of coal tar[J]. Energy Fuels,2020,34(11):13614−13624. doi: 10.1021/acs.energyfuels.0c02096 [2] BAI Z, HUANG P, WANG L, et al. A study on upgrading light coal tar to aerospace fuel[J]. J Fuel Chem Technol,2021,49(5):694−702. doi: 10.1016/S1872-5813(21)60062-2 [3] ZHU Y, LI G, YANG T, et al. Tracing the composition and structure evolution of oxygen-enriched asphaltenes during the hydrotreating of middle-low temperature coal tar[J]. J Anal Appl Pyrolysis,2022,168:105780. doi: 10.1016/j.jaap.2022.105780 [4] 郑舒丹, 安良成. 加氢裂化尾油异构脱蜡催化剂的研究进展[J]. 合成材料老化与应用,2022,51(2):114−116. doi: 10.16584/j.cnki.issn1671-5381.2022.02.048ZHENG Shudan, AN Liangcheng. Research progress of isomerization dewaxing catalysts for hydrocracking tail oil[J]. Synth Mater Aging Appl,2022,51(2):114−116. doi: 10.16584/j.cnki.issn1671-5381.2022.02.048 [5] ZHANG M, ZANG X. Application of principal-component analysis to the interpretation of coal tar physico-chemical properties[J]. Fuel,2023,338:127304. doi: 10.1016/j.fuel.2022.127304 [6] 许海龙, 徐岩峰, 张翠侦, 等. 加氢裂化尾油异构脱蜡-补充精制产品探索研究[J]. 现代化工,2021,41(5):208−211, 216.XU Hailong, XU Yanfeng, ZHANG Cuizhen, et al. Study on hydrocracking tail oil isomerization dewaxing and supplementary refined products[J]. Mod Chem Ind,2021,41(5):208−211, 216. [7] PRAJAPATI R, KOHLI K, MAITY S K. Slurry phase hydrocracking of heavy oil and residue to produce lighter fuels: an experimental review[J]. Fuel,2020,288:119686. [8] YU G, QIU M, WANG T, et al. Optimization of the pore structure and acidity of SAPO-11 for highly efficient hydroisomerization on the long-chain alkane[J]. Microporous Mesoporous Mater,2021,320:111076. doi: 10.1016/j.micromeso.2021.111076 [9] DAI X, CHENG Y, SI M, et al. Synthesis of nickel in situ modified SAPO-11 molecular sieves and hydroisomerization performance of their NiWS supported catalysts[J]. Front Chem,2021,9:765573. doi: 10.3389/fchem.2021.765573 [10] GE L, YU G, CHEN X, et al. Effects of particle size on bifunctional Pt/SAPO-11 catalysts in the hydroisomerization of n-dodecane[J]. New J Chem,2020,44(7):2996−3003. doi: 10.1039/C9NJ06215G [11] 宋成业. ZSM-22/ZSM-23共晶分子筛的合成及加氢异构性能[D]. 大连: 大连理工大学, 2021.SONG Chengye. Synthesis and hydroisomerization of ZSM-22/ZSM-23 eutectic zeolite[D]. Dalian: Dalian University of Technology, 2021. [12] 白迪, 孟记朋, 邹驰, 等. 引入Al2O3对Pt/ZSM-23催化剂加氢异构性能的调控[J]. 燃料化学学报(中英文),2023,51(2):175−185. doi: 10.1016/S1872-5813(22)60034-3BAI Di, MENG Jipeng, ZOU Chi, et al. Regulation of hydrogenation isomerism of Pt/ZSM-23 catalyst by introducing Al2O3[J]. J Fuel Chem Technol,2023,51(2):175−185. doi: 10.1016/S1872-5813(22)60034-3 [13] ZHAO W, LIU L, NIU X, et al. Reaction pathways control of long-chain alkanes hydroisomerization and hydrocracking via tailoring the metal-acid sites intimacy[J]. Fuel,2023,349:128703. doi: 10.1016/j.fuel.2023.128703 [14] CHENG K, SMULDERS L C, VAN DER WAL L I, et al. Maximizing noble metal utilization in solid catalysts by control of nanoparticle location[J]. Science,2022,377(6602):204−208. doi: 10.1126/science.abn8289 [15] KAZAKOV M O, SMIRNOVA M Y, DUBININ M E, et al. Combining USY and ZSM-23 in Pt/zeolite hydrocracking catalyst to produce diesel and lube base oil with improved cold flow properties[J]. Fuel,2023,344:128085. doi: 10.1016/j.fuel.2023.128085 [16] CRESPO I, PALOS R, TRUEBA D, et al. Intensifying gasoline production in the hydrocracking of pre-hydrotreated light cycle oil by means of Pt and Pd supported on a spent FCC catalyst[J]. Fuel,2023,334:126579. doi: 10.1016/j.fuel.2022.126579 [17] ZHAN W, LYU Y, LIU X, et al. The direct synthesis of Ni/SAPO-11 hydroisomerization catalyst via a novel two-step crystallization strategy[J]. Petrol Sci,2022,19(5):2448−2459. doi: 10.1016/j.petsci.2022.01.014 [18] ZHANG X, DENG J, LAN T, et al. Coking-and sintering-resistant Ni nanocatalysts confined by active BN edges for methane dry reforming[J]. ACS Appl Mater Inter,2022,14(22):25439−25447. doi: 10.1021/acsami.2c04149 [19] DAI X, CHENG Y, WEI Q, et al. Small-crystal and hierarchical SAPO-11 molecular sieve synthesized via three-stage crystallization method and hydroisomerization performance of corresponding NiWS supported catalyst[J]. Fuel,2022,324:124610. doi: 10.1016/j.fuel.2022.124610 [20] CHEN Y, LI C, CHEN X, et al. Synthesis of ZSM-23 zeolite with dual structure directing agents for hydroisomerization of n-hexadecane[J]. Microporous Mesoporous Mater,2018,268(2018):216−224. [21] YANG Z, LIU Y, LIU D, et al. Hydroisomerization of n-octane over bimetallic Ni-Cu/SAPO-11 catalysts[J]. Appl Catal A: Gen,2017,543:274−282. doi: 10.1016/j.apcata.2017.06.028 [22] XING G, LIU S, GUAN Q, et al. Investigation on hydroisomerization and hydrocracking of C15–C18 n-alkanes utilizing a hollow tubular Ni-Mo/SAPO-11 catalyst with high selectivity of jet fuel[J]. Catal Today,2019,330:109−116. doi: 10.1016/j.cattod.2018.04.028 [23] 王东旭. Pt与NiMo双金属组分催化剂的限域制备及催化加氢性能研究[D]. 哈尔滨: 黑龙江大学, 2021.WANG Dongxu. Limited preparation and catalytic hydrogenation performance of Pt and NiMo bimetallic catalysts[D]. Harbin: Heilongjiang University, 2021. [24] 白宜灵. Ni/ZSM-22 分子筛在费托油品加氢异构化反应中的研究[D]. 北京: 中国科学院大学 (中国科学院过程工程研究所), 2019.BAI Yiling. Study on the hydroisomerization of Fischer-Tropsch oil by Ni/ZSM-22 molecular sieve[D]. Beijing: University of Chinese Academy of Sciences (Institute of Process Engineering, CAS), 2019. [25] 王斐, 钟梅, 李建, 等. 机械球磨法制备NiMo 催化剂及其在菲加氢中的应用[J]. 燃料化学学报(中英文),2023,51(2):165−174.WANG Fei, ZHONG Mei, Li Jian, et al. Preparation of NiMo catalyst by mechanical ball milling and its application in the hydrogenation of phenylene[J]. J Fuel Chem Technol,2023,51(2):165−174. [26] 翟建荣, 张艳敏, 莫文龙, 等. 制备方法对煤焦油模型化合物裂解催化剂Ni/Al2O3结构及性能的影响[J]. 燃料化学学报,2018,46(9):1063−1073.ZHAI Jianrong, ZHANG Yanmin, MO Wenlong, et al. Effect of preparation method on structure and properties of Ni/Al2O3 catalyst for pyrolysis of coal tar model compound[J]. J Fuel Chem Technol,2018,46(9):1063−1073. [27] DAI X, CHENG Y, SI M, et al. A non-noble metal supported catalyst with potential prospect for hydroisomerization of n-hexadecane: second metal incorporated NiMe/SAPO-11 catalyst with superior hydroisomerization performance[J]. Fuel,2022,324:124517. doi: 10.1016/j.fuel.2022.124517 [28] ZHANG Y, WANG W, JIANG X, et al. Hydroisomerization of n-hexadecane over a Pd-Ni2P/SAPO-31 bifunctional catalyst: synergistic effects of bimetallic active sites[J]. Catal Sci Technol,2018,8(3):817−828. doi: 10.1039/C7CY02106B [29] LIU X, KONG L, LIU C, et al. Study on the formation process of MoO3/Fe2(MoO4)3 by mechanochemical synthesis and their catalytic performance in methanol to formaldehyde[J]. J Therm Anal Calorim,2020,142(4):1363−1376. doi: 10.1007/s10973-020-09483-4 [30] 叶梓良. C9石油树脂加氢双金属催化剂的研究[D]. 北京: 北京化工大学, 2022.YE Ziliang. Study on bimetallic catalyst for hydrogenation of C9 petroleum resin[D]. Beijing: Beijing University of Chemical Technology, 2022. [31] WEN C, XU J, WANG X, et al. n-Heptane hydroisomerization over a SO4 2–/ZrO2@ SAPO-11 composite-based catalyst derived from the growth of UiO-66 on SAPO-11[J]. Energy Fuels,2020,34(8):9498−9508. doi: 10.1021/acs.energyfuels.0c01634 [32] LIU S, REN J, ZHANG H, et al. Synthesis, characterization and isomerization performance of micro/mesoporous materials based on H-ZSM-22 zeolite[J]. J Catal,2016,335:11−23. doi: 10.1016/j.jcat.2015.12.009 [33] WANG D, ZHU Y, TIAN C, et al. Synergistic effect of Mo2N and Pt for promoted selective hydrogenation of cinnamaldehyde over Pt-Mo2N/SBA-15[J]. Catal Sci Technol,2016,6(7):2403−2412. doi: 10.1039/C5CY01654A [34] KWON D W, PARK K H, HONG S C. Enhancement of SCR activity and SO2 resistance on VOx/TiO2 catalyst by addition of molybdenum[J]. Chem Eng J,2016,284:315−324. doi: 10.1016/j.cej.2015.08.152 [35] WANG Y, LI X, ZHANG M, et al. Highly active and durable single-atom tungsten-doped NiS0.5Se0.5 nanosheet @ NiS0.5Se0.5 nanorod heterostructures for water splitting[J]. Adv Mater,2022,34(13):2107053. doi: 10.1002/adma.202107053 [36] YANG L, XING S, SUN H, et al. Citric-acid-induced mesoporous SAPO-11 loaded with highly dispersed nickel for enhanced hydroisomerization of oleic acid to iso-alkanes[J]. Fuel Process Technol,2019,187:52−62. doi: 10.1016/j.fuproc.2019.01.008 [37] YANG F, LIBRETTO N J, KOMARNENI M R, et al. Enhancement of m-cresol hydrodeoxygenation selectivity on Ni catalysts by surface decoration of MoOx species[J]. ACS Catal,2019,9(9):7791−7800. doi: 10.1021/acscatal.9b01285 [38] GARCÍA-PÉREZ D, ALVAREZ-GALVAN M C, CAMPOS-MARTIN J M, et al. Influence of the reduction temperature and the nature of the support on the performance of zirconia and alumina-supported Pt catalysts for n-dodecane hydroisomerization[J]. Catalysts,2021,11(1):88. doi: 10.3390/catal11010088 [39] GUZMAN-BUCIO D M, GOMEZ-SOSA G, CABERA-GERMAN D, et al. Detailed peak fitting analysis of the Ni 2p photoemission spectrum for metallic nickel and an initial oxidation[J]. J Electron Spectrosc,2023,262:147284. [40] KOU T, CHEN M, WU F, et al. Carbon doping switching on the hydrogen adsorption activity of NiO for hydrogen evolution reaction[J]. Nat Commun,2020,11(1):1−10. doi: 10.1038/s41467-019-13993-7 [41] BEHLING R, VALANGE S, CHATEL G. Heterogeneous catalytic oxidation for lignin valorization into valuable chemicals: what results? what limitations? What trends?[J]. Green Chem,2016,18(7):1839−1854. doi: 10.1039/C5GC03061G [42] YU J, LIANG J, CHEN X, et al. Synergistic effect of Ni/W/Cu on MgAl2O4 for one-pot hydrogenolysis of cellulose to ethylene glycol at a low H2 pressure[J]. ACS Omega,2021,6(17):11650−11659. doi: 10.1021/acsomega.1c00979 [43] YAN H, XIE Y, WU A, et al. Anion-modulated HER and OER activities of 3D Ni-V-based interstitial compound heterojunctions for high-efficiency and stable overall water splitting[J]. Adv Mater,2019,31(23):1901174. doi: 10.1002/adma.201901174 [44] GAO R, PAN L, WANG H, et al. Ultradispersed nickel phosphide on phosphorus-doped carbon with tailored d-band center for efficient and chemoselective hydrogenation of nitroarenes[J]. ACS Catal,2018,8(9):8420−8429. doi: 10.1021/acscatal.8b02091 [45] LYU Y, YU Z, YANG Y, et al. Metal-acid balance in the in-situ solid synthesized Ni/SAPO-11 catalyst for n-hexane hydroisomerization[J]. Fuel,2019,243:398−405. doi: 10.1016/j.fuel.2019.01.013 [46] WANG D, KANG X, GU Y, et al. Electronic tuning of Ni by Mo species for highly efficient hydroisomerization of n-alkanes comparable to Pt-based catalysts[J]. ACS Cataly,2020,10(18):10449−10458. doi: 10.1021/acscatal.0c01159 [47] PEYROVI M, PARSAFARD N, HAJIABADI M A. Ni-W catalysts supported on HZSM-5/HMS for the hydrogenation reaction of aromatic compounds: effect of Ni/W ratio on activity, stability and kinetics[J]. Int J Chem Kinet,2017,49(4):283−292. doi: 10.1002/kin.21074 [48] GARCÍA-PÉREZ D, BLANCO-BRIEVA G, ALVAREZ-GALVAN M C, et al. Influence of W loading, support type, and preparation method on the performance of zirconia or alumina-supported Pt catalysts for n-dodecane hydroisomerization[J]. Fuel,2022,319:123704. doi: 10.1016/j.fuel.2022.123704 [49] MENG J, BAI D, ZEYAODONG P, et al. Hydroisomerization of n-hexadecane over Pt/ZSM-48 catalysts: effects of metal-acid balance and crystal morphology[J]. Microporous Mesoporous Mater,2022,330:111637. doi: 10.1016/j.micromeso.2021.111637 [50] LIU L, ZHANG M, WANG L, et al. Modulating acid site distribution in MTT channels for controllable hydroisomerization of long-chain n-alkanes[J]. Fuel Process Technol,2023,241:107605. doi: 10.1016/j.fuproc.2022.107605 [51] WANG Y, TAO Z, WU B, et al. Effect of metal precursors on the performance of Pt/ZSM-22 catalysts for n-hexadecane hydroisomerization[J]. J Catal,2015,322:1−13. [52] CAI Q, GONG T, YU T, et al. Comparison of hydrocracking and cracking of pyrolytic lignin over different Ni-based catalysts for light aromatics production[J]. Fuel Process Technol,2023,240:107564. doi: 10.1016/j.fuproc.2022.107564 -

下载:

下载: