Recent progress on co-catalytic fast pyrolysis of biomass and waste plastics to produce hydrocarbon-rich liquid fuels

-

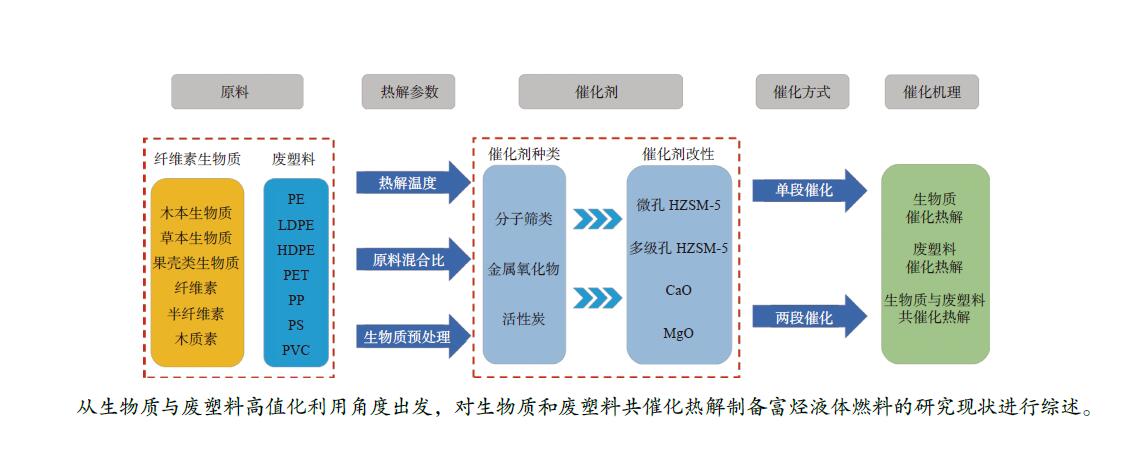

摘要: 生物质能是国际公认的零碳可再生能源,其高效利用成为缓解能源与环境危机的关键,并对中国实现“碳达峰”和 “碳中和”的目标具有重要意义。纤维素生物质与废塑料的共催化热解技术,不仅能制备高附加值的富烃液体燃料,还可达到“以废治废”的目的,进而实现生物质与废塑料的高效资源化利用。本工作从生物质与废塑料高值化利用的角度出发,对生物质和废塑料共催化热解制备富烃液体燃料的研究现状进行了综述,介绍了纤维素生物质和废塑料的基础化学特性差异,论述了废塑料种类、催化剂种类、物料和催化剂比例、催化热解温度等因素对生物质和废塑料共催化热解生物油产率和品质的影响,阐述了生物质和废塑料单独催化热解过程中的化学反应机理,并揭示了共催化热解过程中的协同反应机理,展望了该领域未来的发展方向,为生物质与废塑料的高附加值利用提供参考与思路。Abstract: Biomass energy is recognized as a zero carbon renewable energy source, and the efficient utilization of biomass has become the key to address the energy and environmental crises. It is of great important for China to achieve the goals of “carbon peaking” and “carbon neutrality”. The co-catalytic pyrolysis technology (co-CFP) of biomass and waste plastics can not only produce the value-added hydrocarbon-rich liquid fuels, but achieve the goal of “treating waste with waste” as well, thereby achieving efficient resource utilization of biomass and waste plastics. From the perspective of high value utilization of biomass and waste plastics, this work reviewed the research progress of the co-CFP of biomass and waste plastics to produce hydrocarbon-rich liquid fuels. First, the basic chemical characteristics of cellulose biomass and waste plastics were introduced. The influence of the catalytic pyrolysis temperature, the types of waste plastics, the types of catalyst, the mass ratio of feedstock-to- catalyst on the yield and quality of bio-oil during the co-CFP of biomass and waste plastics was systematically discussed. The synergistic reaction mechanism between biomass and waste plastics was elucidated. Finally, the work forecasted the future development direction of the co-CFP of biomass and waste plastics, and provided reference and ideas for the high value-added utilization of biomass and waste plastics.

-

Key words:

- biomass /

- plastic /

- co-catalytic fast pyrolysis /

- catalyst /

- hydrocarbon-rich liquid fuels

-

表 1 纤维素生物质和塑料的元素分析和工业分析

Table 1 Elemental and proximate analyses of lignocellulosic biomass and waste plastics

Sample Ultimate analysis

w/%Proximate analysis

w/%H/Ceff QHHV/

(MJ·kg−1)C H O N S Cl V FC A Lignocellulosic biomass Woody biomass, pine wood[12] 49.33 6.06 44.57 0.04 0.00 0.00 73.40 16.70 0.50 0.12 19.80 Woody biomass, poplar wood[13] 47.21 6.04 46.74 0.01 0.00 0.00 87.95 10.93 1.12 0.05 18.58 Woody biomass, fir wood[14] 49.07 6.70 44.18 0.02 0.03 0.00 81.93 17.75 0.32 0.29 20.29 Herbaceous biomass, rice straw[15] 36.07 5.20 57.83 0.64 0.26 0.00 78.07 6.93 15.00 −0.67 12.53 Herbaceous biomass, wheat straw[15] 38.34 5.47 55.22 0.60 0.37 0.00 83.08 10.29 6.63 −0.45 13.96 Fruit shell biomass, palm kernel shell[14] 48.44 6.23 44.99 0.31 0.03 0.00 71.72 25.21 3.07 0.15 20.30 Fruit shell biomass, walnut shell[16] 47.30 6.10 42.00 0.50 0.10 0.00 76.60 19.40 4.00 0.22 19.11 Waste plastics Polyethylene (PE)[17] 85.50 14.50 0.00 0.00 0.00 0.00 99.96 0.04 0.00 2.04 46.01 High density polyethylene (HDPE)[6] 85.16 14.48 0.31 0.02 0.03 0.00 99.85 0.06 0.09 2.03 49.63 Low density polyethylene (LDPE)[13] 84.21 14.29 1.47 0.03 0.00 0.00 99.79 0.21 0.00 2.01 48.83 Linear low density polyethylene (LLDPE)[18] 85.61 14.29 0.02 0.05 0.03 0.00 99.85 0.07 0.05 2.00 46.17 Polypropylene (PP)[19] 84.70 15.30 0.00 0.00 2.10 0.00 96.90 0.00 1.00 2.17 45.23 Polystyrene (PS)[17] 92.20 7.80 0.00 0.00 0.00 0.00 99.50 0.50 0.00 1.02 40.49 Polyvinyl chloride (PVC)[20] 38.70 4.80 0.00 0.00 0.00 56.5 95.80 4.20 0.00 1.49 19.30 Polyethylene terephthalate (PET)[19] 64.10 3.70 34.20 0.00 0.00 0.00 84.10 13.90 0.00 −0.01 24.15 H/Ceff: hydrogen-to-carbon effective ratio. 表 2 基于HZSM-5分子筛催化剂的生物质与废塑料共催化热解的相关研究

Table 2 Catalytic co-pyrolysis of biomass and waste plastics by using HZSM-5 as catalyst

Biomas Plastic Mass ratio of biomass-to-plastic Catalyst Pyrolysis temperature/

℃Pyrolysis device Main conclusion Corn stalk HDPE 1:1 HZSM-5 400−800 Py-GC/MS the H/Ceff ratio of feedstock should be adjusted to be >1.0 so that achieved high content of aromatics[21] Switchgrass HDPE 1:1 HZSM-5 650 Py-GC/MS the addition of HDPE is beneficial for the generation of aromatics and reduces coke deposition[22] Red oak PE 1:1 HZSM-5 500−700 Py-GC/MS higher pyrolysis or catalyst temperatures promoted the yield of aromatic hydrocarbons monotonically[23] Pine sawdust PE 1:1 HZSM-5 400−650 fluidized bed reactor the maximum carbon yield of petrochemicals (71%) was obtained at 600 ℃ and polyethylene/pine sawdust ratio of 4:1[24] Cellulose LDPE 1:1 HZSM-5 650 Py-GC/MS CFP of the cellulose and LDPE mixture produced a much higher aromatic carbon yield (47.46%)[25] Walnut shell LDPE 1:1 HZSM-5 550 Py-GC/MS the selectivity toward aromatics is as high as 82.5% during TSCCP process[16] Laminaria japonica PP 1:1 HZSM-5 600 Py-GC/MS MFI type catalyst showed high catalytic upgrading capability during catalytic co-pyrolysis of polypropylene and Laminaria japonica[26] Cellulose PP 1:3 HZSM-5 550 Py-GC/MS/TCD/FID the maximum BTEXs yield (33.4%) achieved at the ratio of 3:1 with samples and the ratio of 1:3 with catalyst[27] Pine wood PVC 3:1, 1:1, 1:3 HZSM-5 600 fixed bed reactor the interaction of biomass and plastic materials decreased the H/C atomic ratio of char, which resulted in a higher chemical stability of char[28] Olive pomace/almond shell PVC 1:2 HZSM-5 650 Py-GC/MS-FGA BTX yields enhanced up to 25% at biomass/plastic ratio of 1:1.5 with the presence of HZSM-5[29] Poplar wood PET 1:1 HZSM-5 600 TG-GC/MS the two-stage catalytic co-pyrolysis over in-situ calcium oxide and ex-situ HZSM-5 produced the much larger amounts of BTEXs[30] Sugarcane bagasse pith PET 1:0, 1:1, 1:2,

1:3, 1:4HZSM-5 400−800 Py-GC/MS the catalyst combination as well as biomass/plastic mixtures used in this work can lead to both high yields of valuable aromatic chemicals[31] Karanja and Niger seeds PS 1:1, 2:1,

4:1, 8:1HZSM-5 500−600 cylindrical furnace co-pyrolysis of waste polystyrene and biomass altered the composition of pyrolytic oil which had a positive influence on the quality of co-pyrolytic oil[32] Pine sawdust PS 1:1 HZSM-5 400−650 fluidized bed reactor catalytic co-pyrolysis of polystyrene and pine sawdust produced the highest and lowest yields of aromatics (47%) and olefins (11.4%), respectively[24] -

[1] 《中共中央国务院关于完整准确全面贯彻新发展理念做好碳达峰碳中和工作的意见》[EB/OL]. http://www.gov.cn/zhengce/2021-10/24/content_5644613.htm, 2021-10-24.《Opinions of the fully implementing the new development concept on carbon peaking and carbon neutrality issued by the Central Committee of the Communist Party of China and the State Council》[EB/OL]. http://www.gov.cn/zhengce/2021-10/24/content_5644613.htm, 2021-10-24. [2] 中国产业发展促进会生物质能产业分会, 德国国际合作机构, 生态环境部环境工程评估中心, 等. 3060零碳生物质能发展潜力蓝皮书 [R/OL]. https://huanbao.bjx.com.cn/news/20210915/1177039.shtml, 2021-09-15.Branch Committee of Bio-energy Industrial of Chinese Industrial Development Committee, Gesellschaft für Internationale Zusammenarbeit, National Center for Environmental Assessment, et al. 3060 Blue book on the development potential of zero carbon biomass energy. [R/OL]. https://huanbao.bjx.com.cn/news/20210915/1177039.shtml, 2021-09-15. [3] WANG S R, DAI G X, YANG H P, et al. Lignocellulosic biomass pyrolysis mechanism: A state-of-the-art review[J]. Prog Energ Combust,2017,62:33−86. doi: 10.1016/j.pecs.2017.05.004 [4] 张会岩, 杨海平, 陆强, 等. 生物质定向热解制取高品质液体燃料, 化学品和碳材料研究进展[J]. 工程热物理学报,2021,42(12):3031−3044.ZHANG Huiyan, YANG Haiping, LU Qiang, et al. Progress of directional pyrolysis of biomass to produce high-quality liquid fuels, chemicals and carbon materials[J]. Jo Eng Therm,2021,42(12):3031−3044. [5] LIU R H, Sarker M, Rahman M M, et al. Multi-scale complexities of solid acid catalysts in the catalytic fast pyrolysis of biomass for bio-oil production–A review[J]. Prog Energy Combust,2020,80:100852. doi: 10.1016/j.pecs.2020.100852 [6] 朱亮, 黄明, 丁紫霞, 等. 烘焙脱氧毛竹与高密度聚乙烯共催化热解制备轻质芳烃[J]. 燃烧化学学报,2022,50(8):993−1003.ZHU Liang, HUANG Ming, DING Zixia, et al. Production of light bio-aromatics from co-catalytic fast pyrolysis of torrefied bamboo and high-density polyethylene[J]. J Fuel Chem Technol,2022,50(8):993−1003. [7] 华经产业研究院. 2022年全球及中国塑料回收行业发展现状分析, 国内塑料回收利用量世界第一[EB/OL]. https://www.huaon.com/channel/trend/853652.html, 2022-11-26.Huajing Industrial Research Institure, et al. Analysis on the development status of global and Chinese plastic recycling industrial in 2022, China is the largest amount of plastic recycling and utilization in the world[EB/OL]. https://www.huaon.com/channel/trend/853652.html, 2022-11-26. [8] LEE K, JING Y X, WANG Y Q, et al. A unified view on catalytic conversion of biomass and waste plastics[J]. Nat Rev Chem,2022,6(9):635−652. doi: 10.1038/s41570-022-00411-8 [9] ZHANG X S, LEI H W, CHEN S L, et al. Catalytic co-pyrolysis of lignocellulosic biomass with polymers: a critical review[J]. Green Chem,2016,18(15):4145−4169. doi: 10.1039/C6GC00911E [10] WANG Z W, BURRA K G, LEI T Z, et al. Co-pyrolysis of waste plastic and solid biomass for synergistic production of biofuels and chemicals-A review[J]. Prog Energ Combust,2021,84:100899. doi: 10.1016/j.pecs.2020.100899 [11] 蔡伟, 黄明, 朱亮, 等. 杨木湿法烘焙预处理耦合金属改性多级孔分子筛催化热解制取轻质芳烃[J]. 燃料化学学报(中英文),2023,51(8):1126−1136.CAI Wei, HUANG Ming, ZHU Liang, et al. Enhancement of the production of light aromatics from poplar wood by combined approach of wet torrefaction pretreatment and catalytic fast pyrolysis using metal modified hierarchical zeolite[J]. J Fuel Chem Technol,2023,51(8):1126−1136. [12] ARREGI A, AMUTIO M, LOPEZ G, et al. Hydrogen-rich gas production by continuous pyrolysis and in-line catalytic reforming of pine wood waste and HDPE mixtures[J]. Energy Convers Manage,2017,136:192−201. doi: 10.1016/j.enconman.2017.01.008 [13] 黄明, 朱亮, 丁紫霞, 等. 生物质三组分与低密度聚乙烯共催化热解制取轻质芳烃的协同作用机理[J]. 化工学报,2022,73(2):699−711.HUANG Ming, ZHU Liang, DING Zixia, et al. Synergistic interactions of biomass three-component and low-density polyethylene during co-catalytic fast pyrolysis for the production of light aromatics[J]. CIESC J,2022,73(2):699−711. [14] XU J L, HUANG M, HU Z Y, et al. Prediction and modeling of the basic properties of biomass after torrefaction pretreatment[J]. J Anal Appl Pyrol,2021,159:105287. doi: 10.1016/j.jaap.2021.105287 [15] BIJOY B, NIDHI P, YASHASVI B, et al. Pyrolysis of agricultural biomass residues: Comparative study of corn cob, wheat straw, rice straw and rice husk[J]. Bioresour Technol,2017,237:57−63. doi: 10.1016/j.biortech.2017.02.046 [16] YU DX, HUI H L, LI S G. Two-step catalytic co-pyrolysis of walnut shell and LDPE for aromatic-rich oil[J]. Energy Convers Manage,2019,198(2019):111816. [17] ZHANG H Y, XIAO R, NIE J L, et al. Catalytic pyrolysis of black-liquor lignin by co-feeding with different plastics in a fluidized bed reactor[J]. Bioresour Technol,2015,192(215):68−74. [18] YUAN Z L, ZHANG J, ZHAO P T, et al. Synergistic effect and chlorine-release behaviors during co-pyrolysis of LLDPE, PP, and PVC[J]. ACS Omega,2020,5(20):11291−11298. doi: 10.1021/acsomega.9b04116 [19] CHATTOPADHYAY J, PATHAK T S, SRIVASTAVA R, et al. Catalytic co-pyrolysis of paper biomass and plastic mixtures (HDPE (high density polyethylene), PP (polypropylene) and PET (polyethylene terephthalate)) and product analysis[J]. Energy,2016,103(2016):513−521. [20] AUGUSTINA E, DOAN P M, DAMIEN L, et al. Co-pyrolysis of wood and plastics: Influence of plastic type and content on product yield, gas composition and quality[J]. Fuel,2018,231:110−117. doi: 10.1016/j.fuel.2018.04.140 [21] ZHANG B, ZHONG Z P, DING K, et al. Production of aromatic hydrocarbons from catalytic co-pyrolysis of biomass and high density polyethylene: Analytical Py-GC/MS study[J]. Fuel,2015,139:622−628. doi: 10.1016/j.fuel.2014.09.052 [22] MULLEN C A. , DORADO C, BOATENG A A. Catalytic co-pyrolysis of switchgrass and polyethylene over HZSM-5: Catalyst deactivation and coke formation[J]. J Anal Appl Pyrolysis,2018,129:195−203. doi: 10.1016/j.jaap.2017.11.012 [23] XUE Y, KELKAR A, BAI X L. Catalytic co-pyrolysis of biomass and polyethylene in a tandem micropyrolyzer[J]. Fuel,2016,166:227−236. doi: 10.1016/j.fuel.2015.10.125 [24] ZHANG H Y, NIE J L, XIAO R, et al. Catalytic co-pyrolysis of biomass and different plastics (polyethylene, polypropylene, and polystyrene) to improve hydrocarbon yield in a fluidized-bed reactor[J]. Energy Fuels,2014,28(3):1940−1947. doi: 10.1021/ef4019299 [25] LI X Y, ZHANG H F, LI J, et al. Improving the aromatic production in catalytic fast pyrolysis of cellulose by co-feeding low-density polyethylene[J]. Appl Catal A: Gen,2013,455:114−121. doi: 10.1016/j.apcata.2013.01.038 [26] KIM Y M, LEE H W, CHOI S J, et al. Catalytic co-pyrolysis of polypropylene and Laminaria japonica over zeolitic materials[J]. Int J Hydrogen Energy,2017,42(29):18434−18441. doi: 10.1016/j.ijhydene.2017.04.139 [27] LEE H W, KIM Y M, JAE J, et al. Production of aromatic hydrocarbons via catalytic co-pyrolysis of torrefied cellulose and polypropylene[J]. Energy Convers Manage,2016,129:81−88. doi: 10.1016/j.enconman.2016.10.001 [28] LU P, HUANG Q X, BOURTSALAS A C, et al. Synergistic effects on char and oil produced by the co-pyrolysis of pine wood, polyethylene and polyvinyl chloride[J]. Fuel,2018,230:359−367. doi: 10.1016/j.fuel.2018.05.072 [29] RUIZ A A, SILVA L S, DORADO F. Enhancement of BTX production via catalytic fast pyrolysis of almond shell, olive pomace with polyvinyl chloride mixtures[J]. Process Saf Environ,2022,163:218−226. doi: 10.1016/j.psep.2022.05.029 [30] PARK Y K, JUNG J, RYU S, et al. Catalytic co-pyrolysis of yellow poplar wood and polyethylene terephthalate over two stage calcium oxide-ZSM-5[J]. Appl Energy,2019,250:1706−1718. doi: 10.1016/j.apenergy.2019.05.088 [31] GHORBANNEZHAD P, PARK S, ONWUDILI J A. Co-pyrolysis of biomass and plastic waste over zeolite- and sodium-based catalysts for enhanced yields of hydrocarbon products[J]. Waste Manage,2020,102:909−918. doi: 10.1016/j.wasman.2019.12.006 [32] SHADANGI K P, MOHANTY K. Co-pyrolysis of Karanja and Niger seeds with waste polystyrene to produce liquid fuel[J]. Fuel,2015,153:492−498. doi: 10.1016/j.fuel.2015.03.017 [33] HE T F, ZHONG S Y, LIU C H, et al. Enhancing hydrocarbon production via ex-situ catalytic co-pyrolysis of biomass and high-density polyethylene: Study of synergistic effect and aromatics selectivity[J]. Waste Manage,2021,128:189−199. doi: 10.1016/j.wasman.2021.04.058 [34] LIU W W, HU C W, YANG Y, et al. Influence of ZSM-5 zeolite on the pyrolytic intermediates from the co-pyrolysis of pubescens and LDPE[J]. Energy Convers Manage,2010,51(5):1025−1032. doi: 10.1016/j.enconman.2009.12.005 [35] DING K, HE A, ZHONG D X, et al. Improving hydrocarbon yield via catalytic fast co-pyrolysis of biomass and plastic over ceria and HZSM-5: An analytical pyrolyzer analysis[J]. Bioresour Technol,2018,268:1−8. doi: 10.1016/j.biortech.2018.07.108 [36] ZHOU G Q, LI J, YU Y Q, et al. Optimizing the distribution of aromatic products from catalytic fast pyrolysis of cellulose by ZSM-5 modification with boron and co-feeding of low-density polyethylene[J]. Appl Catal A: Gen,2014,487:45−53. doi: 10.1016/j.apcata.2014.09.009 [37] DORADO C, MULLEN C A, BOATENG A A. Origin of carbon in aromatic and olefin products derived from HZSM-5 catalyzed co-pyrolysis of cellulose and plastics via isotopic labeling[J]. Appl Catal B: Environ,2015,162:338−345. doi: 10.1016/j.apcatb.2014.07.006 [38] ZHANG X S, LEI H W, ZHU L, et al. Optimizing carbon efficiency of jet fuel range alkanes from cellulose co-fed with polyethylene via catalytically combined processes[J]. Bioresour Technol,2016,214:45−54. doi: 10.1016/j.biortech.2016.04.086 [39] DING K, ZHONG Z P, WANG J, et al. Improving hydrocarbon yield from catalytic fast co-pyrolysis of hemicellulose and plastic in the dual-catalyst bed of CaO and HZSM-5[J]. Bioresour Technol,2018,261:86−92. doi: 10.1016/j.biortech.2018.03.138 [40] LI X Y, LI J, ZHOU G Q, et al. Enhancing the production of renewable petrochemicals by co-feeding of biomass with plastics in catalytic fast pyrolysis with ZSM-5 zeolites[J]. Appl Catal A: Gen,2014,481:173−182. doi: 10.1016/j.apcata.2014.05.015 [41] 宋祖威, 仲兆平, 张波, 等. 玉米秸秆和聚丙烯共催化热解试验[J]. 浙江大学学报(工学版),2016,50(2):333−340.SONG Zuwei, ZHONG Zhaoping, ZHANG Bo, et al. Experimental study on catalytic co-pyrolysis of corn stalk and polypropylene[J]. J Zhejiang Uni(Eng Sci),2016,50(2):333−340. [42] ZHOU H, WU C F, ONWUDILI J A, et al. Effect of interactions of PVC and biomass components on the formation of polycyclic aromatic hydrocarbons (PAH) during fast co-pyrolysis[J]. RSC Adv,2015,5(15):11371−11377. doi: 10.1039/C4RA10639C [43] BRADEN J, BAI X L. Production of biofuel precursor chemicals from the mixture of cellulose and polyvinylchloride in polar aprotic solvent[J]. Waste Manage,2018,78:894−902. doi: 10.1016/j.wasman.2018.07.011 [44] WU M G, WANG Z W, CHEN G F, et al. Synergistic effects and products distribution during Co-pyrolysis of biomass and plastics[J]. J Energy Inst,2023,111:101392. [45] CHEN L Y, MA X Q, TANG F F, et al. Comparison of catalytic effect on upgrading bio-oil derived from co-pyrolysis of water hyacinth and scrap tire over multilamellar MFI nanosheets and HZSM-5 [J]. Bioresour Technol, 2020, 312. [46] KURAMOCHI H, NAKAJIMA D, GOTO S, et al. HCl emission during co-pyrolysis of demolition wood with a small amount of PVC film and the effect of wood constituents on HCl emission reduction[J]. Fuel,2008,87(13/14):3155−3157. doi: 10.1016/j.fuel.2008.03.021 [47] MATSUZAWA Y, AYABE M, NISHINO J. Acceleration of cellulose co-pyrolysis with polymer[J]. Polym Degrad Stabil,2001,71(3):435−444. doi: 10.1016/S0141-3910(00)00195-6 [48] ANDREW C D, MOHAMAD A N, PAUL T W. Catalytic co-pyrolysis of biomass and waste plastics as a route to upgraded bio-oil[J]. J Energy Inst,2021,97:27−36. doi: 10.1016/j.joei.2021.03.022 [49] HASSAN E B, ELSAYED I, ESEYIN A. Production high yields of aromatic hydrocarbons through catalytic fast pyrolysis of torrefied wood and polystyrene[J]. Fuel,2016,174:317−324. doi: 10.1016/j.fuel.2016.02.031 [50] ZHANG X S, LEI H W, ZHU L, et al. Enhancement of jet fuel range alkanes from co-feeding of lignocellulosic biomass with plastics via tandem catalytic conversions[J]. Appl Energy,2016,173:418−430. doi: 10.1016/j.apenergy.2016.04.071 [51] CHEN D Y, WANG Y, LIU Y X, et al. Comparative study on the pyrolysis behaviors of rice straw under different washing pretreatments of water, acid solution, and aqueous phase bio-oil by using TG-FTIR and Py-GC/MS[J]. Fuel,2019,252:1−9. doi: 10.1016/j.fuel.2019.04.086 [52] XUE Y, BAI X L. Synergistic enhancement of product quality through fast co-pyrolysis of acid pretreated biomass and waste plastic[J]. Energy Convers Manage,2018,164:629−638. doi: 10.1016/j.enconman.2018.03.036 [53] MA Z Q, ZHANG Y, SHEN Y F, et al. Oxygen migration characteristics during bamboo torrefaction process based on the properties of torrefied solid, gaseous, and liquid products[J]. Biomass Bioenergy,2019,128:105300. doi: 10.1016/j.biombioe.2019.105300 [54] LIN X N, KONG L S, REN X J, et al. Catalytic co-pyrolysis of torrefied poplar wood and high-density polyethylene over hierarchical HZSM-5 for mono-aromatics production[J]. Renewable Energy,2021,164:87−95. doi: 10.1016/j.renene.2020.09.071 [55] LIKUN P K W, ZHANG H Y, FAN Y Y. Improving hydrocarbons production via catalytic co-pyrolysis of torrefied-biomass with plastics and dual catalytic pyrolysis[J]. Chin J Chem Eng,2022,42:196−209. doi: 10.1016/j.cjche.2020.09.074 [56] KIM Y M, JAE J, KIM B S, et al. Catalytic co-pyrolysis of torrefied yellow poplar and high-density polyethylene using microporous HZSM-5 and mesoporous Al-MCM-41 catalysts[J]. Energy Convers Manage,2017,149:966−973. doi: 10.1016/j.enconman.2017.04.033 [57] SEBESTYÉN Z, RAJNAI E B, BOZI J, et al. Thermo-catalytic pyrolysis of biomass and plastic mixtures using HZSM-5[J]. Appl Energy,2017,207:114−122. doi: 10.1016/j.apenergy.2017.06.032 [58] ENNAERT T, VAN A J, DIJKMANS J, et al. Potential and challenges of zeolite chemistry in the catalytic conversion of biomass[J]. Chem Soc Rev,2016,45(3):584−611. doi: 10.1039/C5CS00859J [59] JIA L Y, RAAD M, HAMIEH S, et al. Catalytic fast pyrolysis of biomass: Superior selectivity of hierarchical zeolites to aromatics[J]. Green Chem,2017,19(22):5442−5459. doi: 10.1039/C7GC02309J [60] CHEN H, CHENG H, ZHOU F, et al. Catalytic fast pyrolysis of rice straw to aromatic compounds over hierarchical HZSM-5 produced by alkali treatment and metal-modification[J]. J Anal Appl Pyrolysis,2018,131:76−84. doi: 10.1016/j.jaap.2018.02.009 [61] STEFANIDIS S D, KALOGIANNIS K G, ILIOPOULOU E F, et al. In-situ upgrading of biomass pyrolysis vapors: Catalyst screening on a fixed bed reactor[J]. Bioresour Technol,2011,102(17):8261−8267. doi: 10.1016/j.biortech.2011.06.032 [62] LIN Y Y, ZHANG C, ZHANG M C, et al. Deoxygenation of bio-oil during pyrolysis of biomass in the presence of CaO in a fluidized-bed reactor[J]. Energy Fuels,2010,24(10):5686−5695. doi: 10.1021/ef1009605 [63] TORRI C, REINIKAINEN M, LINDFORS C, et al. Investigation on catalytic pyrolysis of pine sawdust: Catalyst screening by Py-GC-MIP-AED[J]. J Anal Appl Pyrolysis,2010,88(1):7−13. doi: 10.1016/j.jaap.2010.02.005 [64] LIN X N, ZHANG Z F, ZHANG Z J, et al. Catalytic fast pyrolysis of a wood-plastic composite with metal oxides as catalysts[J]. Waste Manage,2018,79:38−47. doi: 10.1016/j.wasman.2018.07.021 [65] CHE Q F, YANG M J, WANG X H, et al. Aromatics production with metal oxides and ZSM-5 as catalysts in catalytic pyrolysis of wood sawdust[J]. Fuel Process Technol,2019,188:146−152. doi: 10.1016/j.fuproc.2019.02.016 [66] 赵锦波, 苟鑫, 陈皓, 等. 多级孔分子筛在生物质催化热裂解制备芳烃中的研究进展[J]. 生物加工过程,2019,17(4):329−341.ZHAO Jinbo, GOU Xin, CHEN Hao, et al. Recent advances in aromatic production from biomass via catalytic fast pyrolysis over hierarchical zeolite[J]. Chin J Bioprocess Eng,2019,17(4):329−341. [67] KAN T, STREZOV V, EVANS T, et al. Catalytic pyrolysis of lignocellulosic biomass: A review of variations in process factors and system structure [J]. Renewable Sustainable Energy Rev, 2020, 134. [68] 王树荣, 骆仲泱. 生物质组分热裂解[M]. 北京: 科学出版社. 2013.WANG Shurong, LUO Zhongyang. Pyrloysis of Biomass Components[M]. Beijing: Science Press, 2013. [69] 朱锡锋, 陆强. 生物质热解原理与技术[M]. 北京: 科学出版社. 2014.ZHU Xifeng, LU Qiang. Principles and Technologies of Biomass Pyrolysis[M]. Beijing: Science Press, 2014 [70] 黄明, 朱亮, 马中青, 等. 金属改性分子筛催化热解木质素制取轻质芳烃[J]. 燃料化学学报,2021,49(3):292−302. doi: 10.19906/j.cnki.JFCT.2021021HUANG Ming, ZHU Liang, MA Zhongqing, et al. Production of light aromatics from the fast pyrolysis of lignin catalyzed by metalmodified H-ZSM-5 zeolites[J]. J Fuel Chem Technol,2021,49(3):292−302. doi: 10.19906/j.cnki.JFCT.2021021 [71] LI C, ZHANG C T, GHOLIZADEH M, et al. Different reaction behaviours of light or heavy density polyethylene during the pyrolysis with biochar as the catalyst[J]. J Hazard Mater,2020,399:123075. doi: 10.1016/j.jhazmat.2020.123075 -

下载:

下载: