Research progress of SCR medium temperature denitrification catalyst for cement industry

-

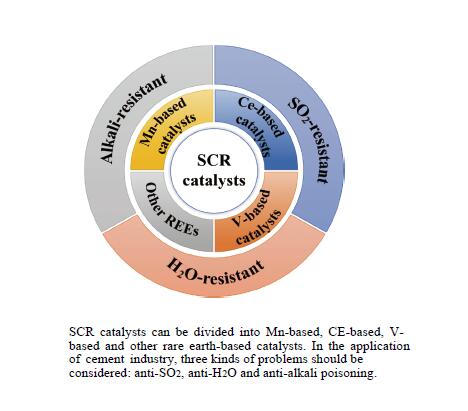

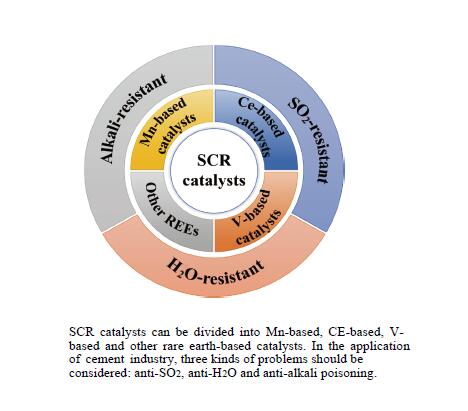

摘要: 选择性催化还原技术(SCR)在水泥行业脱硝中被广泛应用,其中,高温范围内(280–350 ℃)已有较为完善的SCR技术及体系,但在中温区仍有待突破。本工作以中温脱硝催化剂为重点,综述了Mn、Ce、V系脱硝催化剂的研究进展,并分析了Sm、Nb、Ho、Sb、La、Mo、Pr的掺杂对于脱硝催化剂的改性,结合水泥窑炉烟尘中SO2、H2O、碱金属含量高的特点,分析了脱硝催化剂中毒原因,对催化剂的抗H2O、SO2、碱金属中毒性能进行了探讨,展望了水泥行业SCR中温脱硝催化剂的研究前景。Abstract: Selective catalytic reduction (SCR) technology has been widely used in the denitrification of cement industry, in which a relatively mature system has been formed in the high temperature (280–350 ℃) section, but there is still a breakthrough in the middle temperature zone. Focusing on medium temperature catalysts, this paper reviewed the progress of Mn, Ce and V catalysts, and analyzed the doping of Sm, Nb, Ho, Sb, La, Mo and Pr to improve the performance of catalysts. Combined with the characteristics of the high content of SO2, H2O and alkali metal in cement kiln smoke, the causes of catalyst poisoning were analyzed, and the way to resist sulfur poisoning, water poisoning, and alkali metal poisoning was summarized. The research prospect of SCR medium temperature denitration catalyst in cement industry is prospected.

-

Key words:

- selective catalytic reduction /

- de NOx /

- cement denitration /

- alkali metal

-

图 4 3DOM结构下Ce-Fe催化剂的SEM图像[78]

Figure 4 SEM image of Ce-Fe catalyst with 3DOM structure

(with permission from Elsevier)

表 1 Mn系催化剂活性

Table 1 Summary of Mn catalyst activity

Catalyst/Carrier GHSV/h−1 Temperature/℃ Catalyst preparation Reference MnOx 47000 80–150 rheological phase reaction [28] MnOx 47000 80–150 solid [29] Tunneled α-MnO2 38000 120–200 hydrothermal [30] γ-MnO2 30000 140–200 thermal decomposition [31] γ-MnO2 nanosheets 35000 150–230 hydrothermal [32] MnOx 36000 120–180 hydrothermal [33] MnOx-γAl2O3 60000 200–350 impregnation [44] Mn/TiO2 30% 100000 200–300 sol-gel [46] MnTiEu-0.3 36000 180–390 coprecipitation [48] 30%Mn/TiO2-3%Nd 40000 100–350 impregnation [49] 20%Mn-10%Sm/TiO2 80000 110–250 impregnation [50] MnOx-C/C 4000 ~150 impregnation [52] MnOx-CeO2 10600 100–150 impregnation [53] Mn/REC 105000 150–250 in-situ synthesis [54] 表 2 Ce系催化剂活性

Table 2 Summarizes the activity of Ce catalyst

Catalyst/Carrier GHSV/h−1 Temperature/℃ Catalyst preparation Reference CeO2-Ar 36000 120–400 citric acid [57] 50%CeO2-Ti 30000 180–400 coprecipitation [67] 5%Ce-TiO2 50000 275–400 impregnation [69] Ce0.6Ti 50000 300–400 sol-gel [70] Sn(0.1)Mn(0.4)CeOx 35000 80–230 coprecipitation [71] MnOx(0.3)-CeO2 42000 100–180 citric acid [72] MnOx(0.3)-CeO2 42000 120–150 citric acid [73] Mn1Ce9 64000 100–200 surfactant-template [74] Ce0.6Fe0.4O2 90000 200–400 impregnation [77] Ce-Fe(1:0.35) 6000 200–300 microwave hydrothermal [78] Ce-Fe-Ox 18000 250–450 hydrothermal [79] Ce0.3TiF1.5 41000 180–240 coprecipitation [81] CuO-CeO2-TiO2 30000 150–250 sol-gel [82] CeO2/TiO2-MoO3 60000 200–350 hydrothermal [83] Cu-Ce0.25-Zr0.75/TiO2 100000 165–450 impregnation [84] Ce20Nb20Ti 90000 250–450 sol-gel [85] 表 3 V系催化剂活性

Table 3 Summarizes the activity of V-type catalysts

Catalyst/carrier GHSV/h−1 Temperature/℃ Catalyst preparation Reference Ti0.9V0.1O2−δ (304/20) 24000 200–400 Stagnation Premixed

flame system[86] V1Ce5Ti 12800 325–450 impregnation [93] V/Ce1-xTixO2(x = 0.3, 0.5) 70000 190–300 coprecipitation [94] 5V30Ce/TiO2 10000 180–220 impregnation [95] V-W/Ce/Ti-5% 18000 280–450 impregnation [97] V/7Mo-Ti 180000 300–360 impregnation [98] VWSbTi 10000 350–400 impregnation [99] Cr0.2V0.8/TiO2 60000 160–300 impregnation [100] VWCeCuTi 60000 250–375 impregnation [101] 3V3Nb/WTi 60000 225–400 impregnation [102] 表 4 其他稀土改性催化剂活性

Table 4 Summary of activities of other rare earth based catalysts

Catalyst/carrier GHSV/h−1 Temperature/℃ Catalyst preparation Reference 20Mn-10Sm/TiO2 80000 110–250 impregnation [50] Sm-Mn-0.1 48600 75–200 coprecipitation [103] SmCeTi 90000 250–425 coprecipitation [104] MnSmZrTiOx 30000 125–274 coprecipitation [105] MnCeNbTiOx 180000 125–275 coprecipitation [106] Nb-VOx/CeO2 50000 175–350 coprecipitation [108] MnNb0.4Ce0.2Ox 30000 120–240 coprecipitation [109] Fe0.3Ho0.1Mn0.4/TiO2 20000 60–200 impregnation [110] Mn0.4Ce0.07Ho0.1/TiO2 10000 140–220 impregnation [111] Fe0.3Ho0.1Mn0.4/TiO2 20000 60–200 impregnation [112] V2.7Sb2Ti 5000 225–375 impregnation [113] SbV10Ce/TiO2 60000 250–400 impregnation [114] CeSbZrOx 50000 225–350 coprecipitation [115] Sb1.0CeZr2Ox 40000 200–360 citric acid [116] La2.6CuMnOx 24000 250–350 coprecipitation [117] LaMnO3/hematite 9000 150–240 impregnation [120] CeMoTiOx 150000 200–425 coprecipitation [122] Ce40Mo10Ti 90000 250–450 coprecipitation [125] Mo/CeTiOx 48000 200–400 coprecipitation [126] V2O5-MoO3/Pr6O11-TiO2 30000 220–400 sol-gel [127] PrOx(0.2)-MnOx/SAPO-34 40000 140–280 solvent dispersion [128] Fe-Mn/TiO2 (0.02Pr) 30000 140–220 impregnation [129] MnPrOx-0.1 30000 120–220 coprecipitation [130] 表 5 催化剂抗中毒性能

Table 5 Summary of toxic resistance of catalyst

Catalyst/carrier GHSV/h−1 Temperature/℃ Toxic concentration Catalyst preparation Reference Mn-Ce/TiO2 40000 150 1.0×10–4 SO2,3% H2O sol-gel [133] 30Ce6W 36000 250–475 1.0×10–4 SO2 coprecipitation [134] CeSi2 90000 200–400 5.0×10–4 SO2,5% H2O coprecipitation [135] Ce0.6Zr0.4O2 90000 250–300 2.0×10–4 SO2 coprecipitation [137] FeMnOx/Ce 30000 120 1.0×10–4 SO2 citric acid [138] 3V6Nb/WTi 60000 225 5.0×10–4 SO2,5% H2O impregnation [102] MnNb0.4Ce0.2Ox 30000 120–240 2.0×10–4 SO2,7% H2O coprecipitation [109] MnTiEu-0.3 36000 200 5.0×10–5 SO2,5% H2O coprecipitation [48] 2Fe4Co-MCT 12000 200 2.0×10–4 SO2 impregnation [139] Mn0.2Ti0.8O2 60000 150 5% H2O hydrothermal [140] MnCe/GAC-CNTs 10000 150 5.0×10–4 SO2,5% H2O impregnation [143] Mn2Nb1Ox 50000 200 5% H2O coprecipitation [144] MnCo2O4 32000 200 6% H2O coprecipitation [145] MnO2-Co-0.8 50000 200 1.0/2.0×10–4 SO2,5% H2O hydrothermal [146] Ce/TiO2 108000 100–400 Ca/Ce = 0.05 sol-gel [147] Ce/TiO2 108000 100–220 Na:Ce =0.2 sol-gel [148] V/W/Ti 30000 250–400 Ca /V=0, 1, 2, 3 impregnation [149] V2O5/TiO2 96000 310 Ca/V =0–0.2 impregnation [150] P-Ce/TiO2 108000 250–400 K/Ce=0.2 coprecipitation [151] V2O5-WO3/TiO2-CeO2-ZrO2 60000 250–400 K2O=1% coprecipitation [152] V2O5-WO3/TiO2-CeO2-ZrO2 60000 200–450 K2O=1% coprecipitation [153] CeO2-MnOx/TiO2 120000 175–300 K=10/25/50 μmol/g coprecipitation [154] MoO3

(V-HMoO)66000 280–420 K2O=1% hydrothermal [155] K-MnO2 60000 50–200 K=4.22% [156] CeO2-WO3 120000 200–450 CaO=5% impregnation [157] -

[1] 2019年中国水泥行业经济运行报告[J]. 广东建材, 2020, 36(1): 76−78.Economic Operation Report of China cement industry in 2019[J]. Guangdong Building Materials, 2020, 36(1): 76−78. [2] 李海波, 雷华, 李凌霄. 水泥窑烟气SCR脱硝技术应用[J]. 中国水泥,2019,(201):84−86.LI Haibo, LEI Hua, LI Lingxiao. Application of SCR denitrification technology in cement kiln flue gas[J]. China Cement,2019,(201):84−86. [3] 张灵辉. 水泥分解炉燃料型NOx形成影响因素及源头防治研究[D]. 广州: 华南理工大学, 2016.ZHANG Ling-hui. Study on Influencing factors and source prevention of fuel type NOx formation in cement decomposing furnace[D]. Guangdong: South China University of Technology, 2016. [4] 陈柏林. 2022年中国水泥经济运行及2023年展望[J]. 中国水泥,2023,(2):6−10.CHEN Bolin. China Cement economic Operation in 2022 and Outlook in 2023[J]. China Cement,2023,(2):6−10. [5] 张道军, 马子然, 王宝冬, 等. SCR脱硝技术在非电行业烟气治理中的应用进展[J]. 现代化工,2019,39(10):24−28.ZHANG Daojun, MA Ziran, WANG Baodong, et al. Application of SCR denitrification technology in flue gas treatment of non-electric industry[J]. Mod Chem Ind,2019,39(10):24−28. [6] 董贝, 高敏. 水泥窑SCR脱硝系统开发及应用研究[J]. 新世纪水泥导报,2021,27(1):74−77.DONG Bei, GAO Min. Development and application of SCR denitration system in cement kiln.[J]. Cement Guide New Epoch,2021,27(1):74−77. [7] 廖玉云, 毛志伟, 甘昊, 等. 水泥窑低温SCR烟气脱硝催化剂的研究应用[J]. 中国水泥,2016,(8):84−86.LIAO Yuyun, MAO Zhiwei, GAN Hao, et al. Research and application of low-temperature SCR catalyst for flue gas denitrification in cement kilns[J]. China Cement,2016,(8):84−86. [8] XIAODONG W U, LEE H R, LIU S, et al. Sulfur poisoning and regeneration of MnOx -CeO2 -Al2O3 catalyst for soot oxidation[J]. J Rare Earth,2012,30(7):659−664. doi: 10.1016/S1002-0721(12)60108-2 [9] 张柏林, 张生杨, 张深根. 稀土元素在脱硝催化剂中的应用[J]. 化学进展,2022,34(2):301−318.ZHANG Bolin, ZHANG Shengyang, ZHANG Shengen. Application of rare earth elements in denitrification catalysts[J]. Prog Chem,2022,34(2):301−318. [10] 谢玉仙, 刘涛, 苏胜等. 工业窑炉烟气氧含量对钒钛系催化剂NH3-SCR脱硝反应的影响[J]. 化工学报,2022,73(10):4410−4418+4248.XIE Yuxian, LIU Tao, SU Sheng, et al. Effect of oxygen content in flue gas of industrial kiln on NH3-SCR denitrification reaction of vanadium titanium catalysts[J]. CIESC J,2022,73(10):4410−4418+4248. [11] LIU F, SHAN W, SHI X, et al. Research progress in vanadium-free catalysts for the selective catalytic reduction of NO with NH3[J]. Chin J Catal,2011,32(7):1113−1128. [12] 刘兴誉, 张鹏, 贾媛媛等. 基于TiO2载体的锰铈系低温SCR脱硝催化剂研究进展[J]. 化工环保,2020,40(1):26−31.LIU Xingyu, ZHANG Peng, JIA Yuanyuan, et al. Research progress of low-temperature SCR denitration catalysts based on TiO2 support[J]. Environ Prot Chem Ind,2020,40(1):26−31. [13] 马英利, 高凤雨, 贾广如等. SCR脱硝催化剂的发展、应用及其成型工艺综述[J]. 现代化工,2019,39(8):33−37.MA Yingli, GAO Fengyu, JIA Guangru, et al. Review on the development, application and forming process of SCR denitration catalyst[J]. Mod Chem Ind,2019,39(8):33−37. [14] 张涛, 邓立锋, 陈嘉俊等. SCR脱硝技术在水泥窑烟气治理中的应用进展[J]. 环保科技,2021,27(6):61−64.ZHANG Tao, DENG Lifeng, CHEN Jiajun, et al. Progress in the application of SCR denitrification technology in the flue gas treatment of cement kiln[J]. Environ Technol,2021,27(6):61−64. [15] 卢昊, 尹滔. 新型锰基超低温SCR技术在水泥窑炉应用前景分析[J]. 中国水泥,2022,(11):63−66.LU Hao, YIN Tao. Application prospect of new manganese based ultra-low temperature SCR technology in cement kiln[J]. China Cement,2022,(11):63−66. [16] 王海, 韩晨. 水泥窑烟气SCR脱硝技术研究[J]. 能源科技,2023,21(4):93−96.WANG Hai, HAN Chen. Research on SCR denitrification technology of cement kiln flue gas[J]. Energy Technol,2023,21(4):93−96. [17] 程群, 袁子剑. 水泥窑采用SCR脱硝技术的工程应用[J]. 水泥,2023,(4):17−23.CHENG Qun, YUAN Zijian. Engineering application of SCR denitrification technology in cement kiln[J]. Cement,2023,(4):17−23. [18] 张星, 梁丽鹏, 陈洪胜等. 中温中尘SCR脱硝技术在水泥厂实际运行数据分析[J]. 水泥工程,2022,(6):23−24+30.ZHANG Xing, LIANG Lipeng, CHEN Hongsheng, et al. Analysis of the actual running data of the medium temperature and medium dust SCR denitration technology in cement plant[J]. Cement Eng,2022,(6):23−24+30. [19] 张振昆, 卢春林, 汪澜. 中温中尘SCR脱硝技术在水泥窑生产线的应用实践[J]. 水泥,2022,(9):29−31.ZHANG Zhenkun, LU Chunlin, WANG Lan. Application of medium temperature and medium dust SCR denitrification technology in cement kiln production line[J]. Cement,2022,(9):29−31. [20] 盛斌, 段振洪, 汪澜. 中低温SCR脱硝催化剂技术及工程应用案例分析[J]. 水泥,2023,(1):18−22.SHENG Bin, DUAN Zhenhong, WANG Lan. Technology and engineering application case analysis of medium and low temperature SCR denitration catalyst[J]. Cement,2023,(1):18−22. [21] LI Y, LI Y, WAN Y, et al. Structure-performance relationships of MnO2 nanocatalyst for the low-temperature SCR removal of NOx under ammonia[J]. Rsc Adv,2016,6(60):54926−54937. [22] 孟刘邦, 房晶瑞, 马腾坤等. 非负载无定形态Mn-Ce催化剂的脱硝性能分析[J]. 化工环保,2016,36(6):666−670.MENG Liubang, FANG Jingrui, MA Tengkun, et al. Denitration performance analysis of non-supported amorphous Mn-Ce catalyst[J]. Environ Prot Chem Ind,2016,36(6):666−670. [23] DEORSOLA F, ANDREOLI S, ARMANDI M, et al. Unsupported nanostructured Mn oxides obtained by solution combustion synthesis: Textural and surface properties, and catalytic performance in NOx SCR at low temperature[J]. Appl Catal A: Gen,2016,522:120−129. [24] 荣静, 赵婉霞, 骆雯, 等. 用于低温NH3-SCR的Mn基脱硝催化剂研究进展[J]. 工业催化,2022,30(7):1−9.RONG Jing, ZHAO Wanxia, LUO Wen, et al. Research progress of Mn-based denitrification catalysts for low temperature NH3-SCR[J]. Ind Catal,2022,30(7):1−9. [25] KAPTEIJN F, SINGOREDJO L, ANDREINI A, et al. Activity and selectivity of pure manganese oxides in the selective catalytic reduction of nitric oxide with ammonia-ScienceDirect[J]. Appl Catal B: Environ,1994,3(2/3):173−189. doi: 10.1016/0926-3373(93)E0034-9 [26] KANG M, YEON T H, PARK E D, et al. Novel MnOx catalysts for NO reduction at low temperature with ammonia[J]. Catal Lett,2006,106:77−80. doi: 10.1007/s10562-005-9194-3 [27] KANG M, PARK E D, KIM J M, et al. Manganese oxide catalysts for NOx reduction with NH3 at low temperatures[J]. Appl Catal A: Gen,2007,327(2):261−269. doi: 10.1016/j.apcata.2007.05.024 [28] TANG X, HAO J, XU W, et al. Low temperature selective catalytic reduction of NOx with NH3 over amorphous MnOx catalysts prepared by three methods[J]. Catal Commun,2007,8(3):329−334. doi: 10.1016/j.catcom.2006.06.025 [29] 唐晓龙, 郝吉明, 徐文国, 等. 新型MnOx催化剂用于低温NH3选择性催化还原NOx[J]. 催化学报,2006,V27(10):843−848. doi: 10.3321/j.issn:0253-9837.2006.10.003TANG Xiaolong, HAO Jiming, XU Wenguo, et al. A novel MnOx catalyst for selective catalytic reduction of NOx with NH3 at low temperature[J]. Chin J Catal,2006,V27(10):843−848. doi: 10.3321/j.issn:0253-9837.2006.10.003 [30] 戴韵, 李俊华, 彭悦, 等. MnO2的晶相结构和表面性质对低温NH3-SCR反应的影响[J]. 物理化学学报,2012,28(7):1771−1776. doi: 10.3866/PKU.WHXB201204175DAI Yun, LI Junhua, PENG Yue, et al. Effect of crystal phase structure and surface properties of MnO2 on the reaction of NH3-SCR at low temperature[J]. Acta Phys-Chim Sin,2012,28(7):1771−1776. doi: 10.3866/PKU.WHXB201204175 [31] GONG P J, XIE J L, FANG D, et al. Effects of surface physicochemical properties on NH3-SCR activity of MnO2 catalysts with different crystal structures[J]. Chin J Catal,2017,38(11):1925−1934. [32] 孙梦婷, 黄碧纯, 马杰文, 等. 二氧化锰在低温NH3-SCR催化反应上的形貌效应[J]. 物理化学学报,2016,32(6):1501−1510.SUN Mengting, HUANG Bichun, MA Jiewen, et al. Morphology effect of manganese dioxide on catalytic reaction of NH3-SCR at low temperature[J]. Acta Phys-Chim Sin,2016,32(6):1501−1510. [33] SHI J W, CHENLIU, CHANGFAN, et al. Porous MnOx for low-temperature NH3-SCR of NOx: The intrinsic relationship between surface physicochemical property and catalytic activity[J]. J Nanopart Res,2017,19(6):194. [34] 杨洋, 胡准, 米容立, 等. Mn负载量对nMnOx/TiO2催化剂NH3-SCR催化性能的影响[J]. 分子催化,2020,34(4):313−325.YANG Yang, HU Zhun, MI Rongli, et al. Effect of Mn loading on NH3-SCR catalytic performance of nMnOx/TiO2 catalyst[J]. J Mol Catal(Chin),2020,34(4):313−325. [35] 杨永利, 徐东耀, 晁春艳, 等. 负载型Mn基低温NH3-SCR脱硝催化剂研究综述[J]. 化工进展,2016,35(4):1094−1100.YANG Yongli, XU Dongyao, CHAO Chunyan, et al. Research review on supported Mn-based low-temperature NH3-SCR denitration catalysts[J]. Chem Ind Eng Prog,2016,35(4):1094−1100. [36] 王学涛, 张小龙, 焦叶凡, 等. 不同载体负载的Mn系复合氧化物催化剂性能研究[J]. 锅炉技术,2015,46(4):7−11, 80.WANG Xuetao, ZHANG Xiaolong, JIAO Yefan, et al. Study on the properties of Mn series composite oxide catalysts supported by different carriers[J]. Boiler Technol,2015,46(4):7−11, 80. [37] ETTIREDDY P R, ETTIREDDY N, MAMEDOV S, et al. Surface characterization studies of TiO2 supported manganese oxide catalysts for low temperature SCR of NO with NH3[J]. Appl Catal B: Environ,2007,76(1):123−134. [38] HU Y ,DING S ,TAN C , et al. Three-dimensionally ordered macroporous(3DOM) structure promoted the activity and H2O poisoning resistance of Ce Mn/3DOM-TiO2 catalyst in NH3-SCR[J]. J Rare Earth,2024,42(3):523−533. [39] SMIRNIOTIS P G, SREEKANTH P M, PEÑA D A, et al. Manganese oxide catalysts supported on TiO2, Al2O3, and SiO2: A comparison for low-temperature SCR of NO with NH3[J]. Ind Eng Chem Res,2006,45(19):6436−6443. doi: 10.1021/ie060484t [40] YONGDA H, YUHAN Y, HONGYUN H, et al. A deep insight into arsenic adsorption over γ-Al2O3 in the presence of SO2 /NO[J]. Proc Combust Inst,2019,37(3):2951−2957. doi: 10.1016/j.proci.2018.06.136 [41] ZHAO W, TANG Y, WAN Y, et al. Promotion effects of SiO2 or/and Al2O3 doped CeO2 /TiO2 catalysts for selective catalytic reduction of NO by NH3[J]. J Hazard Mater,2014,278:350−359. [42] KONG, TINGTING, YANG, et al. Influence of different supports on the physicochemical properties and denitration performance of the supported Mn-based catalysts for NH3-SCR at low temperature[J]. Appl Surf Sci,2017,402(Apr.30):208−217. [43] KIJLSTRA W S, DAAMEN J, GRAAF J, et al. Inhibiting and deactivating effects of water on the selective catalytic reduction of nitric oxide with ammonia over MnOx /Al2O3[J]. Appl Catal B: Environ,1996,7(3):337−357. [44] 付金艳, 王振峰, 白心蕊等. γ-Al2O3酸性修饰稀土尾矿NH3-SCR脱硝性能[J]. 中国环境科学,2020,40(9):3741−3747.FU Jinyan, WANG Zhenfeng, BAI Xinrui, et al. NH3-SCR denitrification performance of γ-Al2O3 acid modified rare earth tailings[J]. China Environ Sci,2020,40(9):3741−3747. [45] 汤常金, 孙敬方, 董林. 超低温(<150 ℃)SCR脱硝技术研究进展[J]. 化工学报,2020,71(11):4873−84+5362.TANG Changjin, SUN Jingfang, DONG Lin. Ultra-low temperature (<150 ℃) research progress of SCR denitrification technology[J]. CIESC J,2020,71(11):4873−84+5362. [46] JIANG B, LIU Y, WU Z. Low-temperature selective catalytic reduction of NO on MnOx/TiO2 prepared by different methods[J]. J Hazard Mater,2009,162(2/3):1249−1254. doi: 10.1016/j.jhazmat.2008.06.013 [47] KIM Y J, KWON H J, NAM I S. High deNOx performance of Mn/TiO2 catalyst by NH3[J]. Catal Today,2010,(3/4):151. [48] CHEN G, SHI J W, FAN Z, et al. Eu-Mn-Ti mixed oxides for the SCR of NOx with NH3: The effects of Eu-modification on catalytic performance and mechanism[J]. Fuel Process Technol,2017,167:322−333. doi: 10.1016/j.fuproc.2017.07.006 [49] HUANG J, HUANG H, JIANG H, et al. The promotional role of Nd on Mn/TiO2 catalyst for the low-temperature NH3-SCR of NOx[J]. Catal Today,2019,(332):49−58. [50] LIU L, XU K, SU S, et al. Efficient Sm modified Mn/TiO2 catalysts for selective catalytic reduction of NO with NH3 at low temperature[J]. Appl Catal A: Gen,2020,592:117413. doi: 10.1016/j.apcata.2020.117413 [51] LI J, CHANG H, MA L, et al. Low-temperature selective catalytic reduction of NOx with NH3 over metal oxide and zeolite catalysts-A review[J]. Catal Today,2011,175(1):147−156. [52] VALDÉS-SOLS T, MARBÁN G, FUERTES A B. Low-temperature SCR of NOx with NH3 over carbon-ceramic cellular monolith-supported manganese oxides[J]. Catal Today,2001,69(1/4):259−264. doi: 10.1016/S0920-5861(01)00378-9 [53] TANG X L, HAO J M, YI H H, et al. Low-temperature SCR of NO with NH3 over AC/C supported manganese-based monolithic catalysts[J]. Catal Today,2007,126(3/4):406−411. doi: 10.1016/j.cattod.2007.06.013 [54] 张先龙, 胡晓芮, 刘仕雯, 等. 锰基累托石低温NH3-SCR催化剂的制备方法[J]. 环境化学,2022,41(3):1043−1051.ZHANG Xianlong, HU Xiaorui, LIU Shiwen, et al. Preparation of low-temperature NH3-SCR catalyst with manganyl rectorite[J]. Environ Chem,2022,41(3):1043−1051. [55] GUO K, JI J, SONG W, et al. Conquering ammonium bisulfate poison over low-temperature NH3-SCR catalysts: A critical review[J]. Appl Catal B: Environ,2021,297:120388. doi: 10.1016/j.apcatb.2021.120388 [56] KANG K, YAO X, CAO J, et al. Enhancing the K resistance of CeTiOx catalyst in NH3-SCR reaction by CuO modification[J]. J Hazard Mater,2021,402:123551. doi: 10.1016/j.jhazmat.2020.123551 [57] ZHANG B, ZHANG S, LIU B. Effect of oxygen vacancies on ceria catalyst for selective catalytic reduction of NO with NH3[J]. Appl Surf Sci,2020,529:147068. doi: 10.1016/j.apsusc.2020.147068 [58] ZHU C, WEI X, LI W, et al. Crystal-plane effects of CeO2 {110} and CeO2 {100} on photocatalytic CO2 reduction: Synergistic interactions of oxygen defects and hydroxyl groups[J]. ACS Sustainable Chem Eng,2020,8(38):14397−14406. doi: 10.1021/acssuschemeng.0c04205 [59] 乔南利, 杨忆新, 刘清龙, 等. 载体物化性质对锰铈催化剂NH3-SCR脱硝性能的影响[J]. 燃料化学学报,2018,46(6):733−742.QIAO Nanli, YANG Yixin, LIU Qinglong, et al. Effect of physicochemical properties of support on denitration performance of NH3-SCR catalyst[J]. J Fuel Chem Technol,2018,46(6):733−742. [60] 张强, 刘璐, 于梦云等. 氧化铝载体硫酸化对锰铈催化剂SCR脱硝性能的影响[J]. 燃料化学学报,2019,47(9):1137−1145.ZHANG Qiang, LIU Lu, YU Mengyun, et al. Effect of alumina carrier sulfation on denitrification performance of Manganese-cerium catalyst[J]. J Fuel Chem Technol,2019,47(9):1137−1145. [61] GUO R T, LI M Y, SUN P, et al. Mechanistic investigation of the promotion effect of Bi modification on the NH3-SCR performance of Ce/TiO2 catalyst[J]. J Phys Chem C,2017,121(49):27535−27545. doi: 10.1021/acs.jpcc.7b10342 [62] ZHU Y, SHAN W, LIAN Z, et al. Effects of impregnation sequence on the NH3-SCR activity and hydrothermal stability of a Ce-Nb/SnO2 catalyst[J]. J Environ Sci,2024,138(4):450−457. [63] 张光学, 周安琪, 范海燕等. 铁铈氧化物SCR脱硝催化剂的制备及性能[J]. 燃料化学学报,2015,43(10):1267−1272.ZHANG Guangxue, ZHOU Anqi, FAN Haiyan, et al. Preparation and properties of Fe-cerium oxide SCR denitration catalyst[J]. J Fuel Chem Technol,2015,43(10):1267−1272. [64] YAO W, LIU Y, WANG X, et al. The superior performance of sol-gel made Ce-O-P catalyst for Selective catalytic reduction of NO with NH3[J]. J Phys Chem C,2016,120(1):221−229. [65] ZHANG R, ZHONG Q, ZHAO W. Enhanced catalytic performance of F-doped CeO2-TiO2 catalysts in selective catalytic reduction of NO with NH3 at low temperatures[J]. Res Chem Intermediat,2015,41:3479−3490. doi: 10.1007/s11164-013-1465-9 [66] 叶季蕾, 刘源, 闻学兵, 等. CeO2-TiO2 复合氧化物载体在催化中的应用研究进展[J]. 化工进展,2005,24(7):733−736.YE Jilei, LIU Yuan, WEN Xuebing, et al. Research progress of CeO2-TiO2 composite oxide support in catalysis[J]. Chem Ind Eng Prog,2005,24(7):733−736. [67] 孙向丽, 何洪, 苏垚超, 等. 基于NH3-SCR的CeO2-TiO2复合氧化物催化剂: 结构与脱硝性能[J]. 高等学校化学学报,2017,38(5):814−822.SUN Xiangli, HE Hong, SU Yaochao, et al. CeO2-TiO2 composite oxide catalyst based on NH3-SCR: Structure and denitrification performance[J]. Chem J Chin Univ,2017,38(5):814−822. [68] ZHANG W, LIU G, JIANG J, et al. Temperature sensitivity of the selective catalytic reduction (SCR) performance of Ce-TiO2 in the presence of SO2[J]. Chemosphere,2020,243:125419. doi: 10.1016/j.chemosphere.2019.125419 [69] XU W, YU Y, ZHANG C, et al. Selective catalytic reduction of NO by NH3 over a Ce/TiO2 catalyst[J]. Catal Commun,2008,9(6):1453−1457. doi: 10.1016/j.catcom.2007.12.012 [70] GAO X, JIANG Y, ZHONG Y, et al. The activity and characterization of CeO2-TiO2 catalysts prepared by the sol-gel method for selective catalytic reduction of NO with NH3[J]. J Hazard Mater,2010,174(1/3):734−739. doi: 10.1016/j.jhazmat.2009.09.112 [71] CHANG H, LI J, CHEN X, et al. Effect of Sn on MnOx-CeO2 catalyst for SCR of NOx by ammonia: Enhancement of activity and remarkable resistance to SO2[J]. Catal Commun,2012,27:54−57. doi: 10.1016/j.catcom.2012.06.022 [72] QI G, YANG R T. Characterization and FTIR studies of MnOx-CeO2 catalyst for low-temperature selective catalytic reduction of NO with NH3[J]. J Phys Chem B,2004,108(40):15738−15747. doi: 10.1021/jp048431h [73] QI G, YANG R T. Performance and kinetics study for low-temperature SCR of NO with NH3 over MnOx-CeO2 catalyst[J]. J Catal,2003,217(2):434−441. doi: 10.1016/S0021-9517(03)00081-2 [74] LIU Z, YI Y, ZHANG S, et al. Selective catalytic reduction of NOx with NH3 over Mn-Ce mixed oxide catalyst at low temperatures[J]. Catal Today,2013,216:76−81. doi: 10.1016/j.cattod.2013.06.009 [75] MURUGAN B, RAMASWAMY A, SRINIVAS D, et al. Nature of manganese species in Ce1−xMnxO2−δ solid solutions synthesized by the solution combustion route[J]. Chem Mater,2005,17(15):3983−3993. doi: 10.1021/cm050401j [76] 闫东杰, 玉亚, 徐颖, 等. Mn, Ce 负载顺序对催化剂 Mn-Ce/TiO2 低温脱硝活性的影响[J]. 化工进展,2015,34(6):1652−1655.YAN Dongjie, YU Ya, XU Ying, et al. Effect of Mn and Ce loading sequence on low-temperature denitrification activity of Mn-Ce/TiO2 catalysts[J]. Chem Ind Eng Prog,2015,34(6):1652−1655. [77] LIU H, WU Y, LIU L, et al. Three-dimensionally ordered macroporous Fe-doped ceria catalyst with enhanced activity at a wide operating temperature window for selective catalytic reduction of NOx[J]. Appl Surf Sci,2019,498:143780. doi: 10.1016/j.apsusc.2019.143780 [78] ZHANG K, WANG J, GUAN P, et al. Low-temperature NH3-SCR catalytic characteristic of Ce-Fe solid solutions based on rare earth concentrate[J]. Mater Res Bull,2020,128:110871. doi: 10.1016/j.materresbull.2020.110871 [79] 张学军, 张庭基, 宋忠贤, 等. 硫酸盐物种对Ce-Fe-Ox催化剂脱硝性能影响的研究[J]. 燃料化学学报,2021,49(6):844−852. doi: 10.1016/S1872-5813(21)60021-XZHANG Youjun, ZHANG Tingji, SONG Zhongxian, et al. Study on effect of sulfate species on denitration performance of Ce-Fe-Ox catalyst[J]. J Fuel Chem Technol,2021,49(6):844−852. doi: 10.1016/S1872-5813(21)60021-X [80] 张哲, 谢峻林, 方德, 等. CeO2 在SCR低温脱硝催化剂中应用的研究进展[J]. 硅酸盐通报,2014,33(11):2891−2896.ZHANG Zhe, XIE Junlin, FANG De, et al. Research progress on the application of CeO2 in SCR low-temperature denitrification catalysts[J]. Bull Chin Ceramic Soc,2014,33(11):2891−2896. [81] ZHANG R, ZHONG Q, ZHAO W, et al. Promotional effect of fluorine on the selective catalytic reduction of NO with NH3 over CeO2-TiO2 catalyst at low temperature[J]. Appl Surf Sci,2014,289:237−244. doi: 10.1016/j.apsusc.2013.10.143 [82] CHEN L, SI Z, WU X. DRIFT study of CuO-CeO2-TiO2 mixed oxides for NOx reduction with NH3 at low temperatures[J]. ACS Appl Mater Inter,2014,6(11):8134−8145. [83] LI L, TAN W, WEI X, et al. Mo doping as an effective strategy to boost low temperature NH3-SCR performance of CeO2/TiO2 catalysts[J]. Catal Commun,2018,114:10−14. doi: 10.1016/j.catcom.2018.05.015 [84] SUN X, GONG C, LV G, et al. Effect of Ce/Zr molar ratio on the performance of Cu-Cex-Zr1-x/TiO2 catalyst for selective catalytic reduction of NOx with NH3 in diesel exhaust[J]. Mater Res Bull,2014,60:341−347. doi: 10.1016/j.materresbull.2014.09.014 [85] MA S, GAO W, YANG Z, et al. Superior Ce-Nb-Ti oxide catalysts for selective catalytic reduction of NO with NH3[J]. J Energy Inst,2021,94:73−84. doi: 10.1016/j.joei.2020.11.001 [86] CHEN T, LIN H, GUAN B, et al. Promoting the low temperature activity of Ti-V-O catalysts by premixed flame synthesis[J]. Chem Eng J,2016,296:45−55. doi: 10.1016/j.cej.2015.08.115 [87] AMIRIDIS M D, DUEVEL R V, WACHS I E. The effect of metal oxide additives on the activity of V2O5/TiO2 catalysts for the selective catalytic reduction of nitric oxide by ammonia[J]. Appl Catal B: Environ,1999,20(2):111−122. doi: 10.1016/S0926-3373(98)00101-5 [88] DUNN J P, STENGER JR H G, WACHS I E. Oxidation of SO2 over supported metal oxide catalysts[J]. J Catal,1999,181(2):233−243. doi: 10.1006/jcat.1998.2305 [89] LI Y, XIONG J, LIN Y, et al. Distribution of SO2 oxidation products in the SCR of NO over V2O5/TiO2 catalysts at different temperatures[J]. Ind Eng Chem Res,2020,59(11):5177−5185. doi: 10.1021/acs.iecr.9b05271 [90] YOUN S, SONG I, LEE H, et al. Effect of pore structure of TiO2 on the SO2 poisoning over V2O5/TiO2 catalysts for selective catalytic reduction of NOx with NH3[J]. Catal Today,2018,303:19−24. doi: 10.1016/j.cattod.2017.08.015 [91] SONG I, YOUN S, LEE H, et al. Effects of microporous TiO2 support on the catalytic and structural properties of V2O5/microporous TiO2 for the selective catalytic reduction of NO by NH3[J]. Appl Catal B: Environ,2017,210:421−431. doi: 10.1016/j.apcatb.2017.04.016 [92] 段瑞瑞. V4+/V5+比值调变影响因素及其V4+和V5+转化的氧化还原速率与SCR脱硝活性[D]. 哈尔滨: 哈尔滨工程大学, 2014.DUAN Ruirui. Influencing factors of V4+/V5+ ratio modulation and the redox rate of V4+ and V5+ transformation and the denitrification activity of SCR[D]. Harbin: Harbin Engineering University, 2014. [93] LIU Z, ZHANG S, LI J, et al. Novel V2O5-CeO2/TiO2 catalyst with low vanadium loading for the selective catalytic reduction of NOx by NH3[J]. Appl Catal B: Environ,2014,158:11−19. [94] VUONG T H, RADNIK J R, RABEAH J, et al. Efficient VOx/Ce1–xTixO2 catalysts for low-temperature NH3-SCR: Reaction mechanism and active sites assessed by in situ/operando spectroscopy[J]. ACS Catal,2017,7(3):1693−1705. doi: 10.1021/acscatal.6b03223 [95] HUANG Y, TONG Z-Q, BING W, et al. Low temperature selective catalytic reduction of NO by ammonia over V2O5-CeO2/TiO2[J]. J Fuel Chem Technol,2008,36(5):616−620. doi: 10.1016/S1872-5813(08)60036-5 [96] GILLOT S, TRICOT G, VEZIN H, et al. Development of stable and efficient CeVO4 systems for the selective reduction of NOx by ammonia: Structure-activity relationship[J]. Appl Catal B: Environ,2017,218:338−348. doi: 10.1016/j.apcatb.2017.06.049 [97] LI C, SHEN M, WANG J, et al. New insights into the promotional mechanism of ceria for activity and ammonium bisulfate resistance over V/WTi catalyst for selective catalytic reduction of NO with NH3[J]. Appl Catal A: Gen,2018,560:153−164. doi: 10.1016/j.apcata.2018.05.005 [98] KWON D W, PARK K H, HA H P, et al. The role of molybdenum on the enhanced performance and SO2 resistance of V/Mo-Ti catalysts for NH3-SCR[J]. Appl Surf Sci,2019,481:1167−1177. doi: 10.1016/j.apsusc.2019.03.118 [99] SONG H, LIU S, ZHANG M, et al. A comparative study of the NH3-SCR reactions over an original and Sb-modified V2O5-WO3/TiO2 catalyst at low temperatures[J]. Energies,2018,11(12):3339. doi: 10.3390/en11123339 [100] YANG R, HUANG H, CHEN Y, et al. Performance of Cr-doped vanadia/titania catalysts for low-temperature selective catalytic reduction of NOx with NH3[J]. Chin J Catal,2015,36(8):1256−1262. doi: 10.1016/S1872-2067(15)60884-1 [101] LI H, MIAO J, SU Q, et al. Improvement in alkali metal resistance of commercial V2O5-WO3/TiO2 SCR catalysts modified by Ce and Cu[J]. J Mater Sci,2019,54(24):14707−14719. doi: 10.1007/s10853-019-03919-5 [102] ZHU L, ZHONG Z, XUE J, et al. NH3-SCR performance and the resistance to SO2 for Nb doped vanadium based catalyst at low temperatures[J]. J Enviro Sc,2018,65:306−316. doi: 10.1016/j.jes.2017.06.033 [103] MENG D, ZHAN W, GUO Y, et al. A highly effective catalyst of Sm-MnOx for the NH3-SCR of NOx at low temperature: promotional role of Sm and its catalytic performance[J]. ACS Catal,2015,5(10):5973−5983. doi: 10.1021/acscatal.5b00747 [104] LIU H, FAN Z, SUN C, et al. Improved activity and significant SO2 tolerance of samarium modified CeO2-TiO2 catalyst for NO selective catalytic reduction with NH3[J]. Appl Catal B: Environ,2019,244:671−683. doi: 10.1016/j.apcatb.2018.12.001 [105] SUN C, LIU H, CHEN W, et al. Insights into the Sm/Zr co-doping effects on N2 selectivity and SO2 resistance of a MnOx-TiO2 catalyst for the NH3-SCR reaction[J]. Chem Eng J,2018,347:27−40. doi: 10.1016/j.cej.2018.04.029 [106] 赵训志, 王鉴, 张健伟, 等. 铌氧化物的催化应用[J]. 化工时刊,2005,(10):43−46.ZHAO Xunzhi, WANG Jian, ZHANG Jianwei, et al. Catalytic application of niobium oxides[J]. Chem Ind Times,2005,(10):43−46. [107] ZHAO B, RAN R, GUO X, et al. Nb-modified Mn/Ce/Ti catalyst for the selective catalytic reduction of NO with NH3 at low temperature[J]. Appl Catal A: Gen,2017,545:64−71. doi: 10.1016/j.apcata.2017.07.024 [108] LIAN Z, LIU F, HONG H, et al. Nb-doped VOx/CeO2 catalyst for NH3-SCR of NOx at low temperatures[J]. RSC Adv,2015,5(47):37675−37681. doi: 10.1039/C5RA02752G [109] 樊荣, 杨波, 黄琼, 等. Nb改性对MnCe0.2Ox低温SCR抗硫和水热稳定性能的影响[J]. 南京工业大学学报(自然科学版),2020,42(6):751−759.FAN Rong, YANG Bo, HUANG Qiong, et al. Effect of Nb modification on sulfur resistance and hydrothermal stability of MnCe0.2Ox low temperature SCR[J]. J Nanjing Tech Univ (Nat Sci Ed),2020,42(6):751−759. [110] ZHU Y, ZHANG Y, XIAO R, et al. Novel holmium-modified Fe-Mn/TiO2 catalysts with a broad temperature window and high sulfur dioxide tolerance for low-temperature SCR[J]. Catal Commun,2017,88:64−67. doi: 10.1016/j.catcom.2016.09.031 [111] 李伟. Ho改性对Mn-Ce/TiO2催化剂低温SCR性能的影响[D]. 湖北: 华中科技大学, 2019.LI Wei. Effect of Ho modification on low-temperature SCR performance of Mn-Ce/TiO2 catalyst[D]. Hubei: Huazhong University of Science and Technology, 2019. [112] 庄柯, 张亚平, 黄天娇, 等. Ho改性Fe-Mn/TiO2低温SCR脱硝催化剂硫中毒及热还原再生研究[J]. 燃料化学学报,2017,45(11):1356−1364. doi: 10.1016/S1872-5813(17)30060-9ZHUANG Ke, ZHANG Yaping, HUANG Tianjiao, et al. Study on sulfur poisoning and thermal reduction regeneration of Ho modified Fe-Mn/TiO2 low-temperature SCR denitrification catalyst[J]. J Fuel Chem Technol,2017,45(11):1356−1364. doi: 10.1016/S1872-5813(17)30060-9 [113] XU T, WU X, GAO Y, et al. Comparative study on sulfur poisoning of V2O5-Sb2O3/TiO2 and V2O5-WO3/TiO2 monolithic catalysts for low-temperature NH3-SCR[J]. Catal Commun,2017,93:33−36. [114] LEE K J, KUMAR P A, MAQBOOL M S, et al. Ceria added Sb-V2O5 /TiO2 catalysts for low temperature NH3 SCR: Physico-chemical properties and catalytic activity[J]. Appl Catal B: Environ,2013,142:705−711. [115] SHI R H, LIN X Y, ZHENG Z G, et al. Selective catalytic reduction of NOx with NH3 over Sb modified CeZrOx catalyst[J]. React Kinet Mech Cat,2018,124(1):217−227. doi: 10.1007/s11144-017-1314-8 [116] WANG X Q, LIU Y, YAO W Y, et al. Boosting the low-temperature activity and sulfur tolerance of CeZr2Ox catalysts by antimony addition for the selective catalytic reduction of NO with ammonia[J]. J Colloid Interface Sci,2019,546:152−162. doi: 10.1016/j.jcis.2019.03.031 [117] LIU T, WEI L, YAO Y, et al. La promoted CuO-MnOx catalysts for optimizing SCR performance of NO with CO[J]. Appl Surf Sci,2021,546:148971. doi: 10.1016/j.apsusc.2021.148971 [118] ZHAO W, LI C, LU P, et al. Iron, lanthanum and manganese oxides loaded on γ-Al2O3 for selective catalytic reduction of NO with NH3 at low temperature[J]. Environ Technol,2013,34(1):81−90. doi: 10.1080/09593330.2012.680920 [119] REDDY B M, SREEKANTH P M, REDDY E P, et al. Surface Characterization of La2O3-TiO2 and V2O5/La2O3-TiO2 Catalysts[J]. J Phys Chem B,2002,106(22):5695−5700. doi: 10.1021/jp014487p [120] 王瑞, 归柯庭, 梁辉. La1-xCexMnO3/赤铁矿催化剂的制备与低温SCR脱硝特性[J]. 东南大学学报(自然科学版),2016,46(6):1234−1239.WANG Rui, GUI Keting, LIANG Hui. Preparation of La1-xCexMnO3/ Hematite catalyst and its denitrification characteristics with low temperature SCR[J]. J Southeast Univ (Nat Sci Ed),2016,46(6):1234−1239. [121] XIANG L, MING M, JIN-SONG Y, et al. Fine structures of manganese species in highly dispersed Mn/Ce/La/Al2O3 catalysts[J]. Chin J Inorg Chem,2007,23(2):211−216. [122] CHEN X, GENG Y, SHAN W, et al. Deactivation effects of potassium on a CeMoTiOx catalyst for the selective catalytic reduction of NOx with NH3[J]. Ind Eng Chem Res,2018,57:5,1399−1407. [123] LI X, LI X, LI J, et al. Identification of the arsenic resistance on MoO3 doped CeO2/TiO2 catalyst for selective catalytic reduction of NOx with ammonia[J]. J Hazard Mater,2016,318(NOV.15):615−622. [124] WANG H, ZHU T, QIAO Y J, et al. Investigation of the promotion effect of Mo doped CuO catalysts for the low-temperature performance of NH3-SCR reaction[J]. Chin Chem Lett,2022,33(12):5223−5227. doi: 10.1016/j.cclet.2022.01.075 [125] JIANG Y, ZHANG X, LU M Y, et al. Activity and characterization of Ce-Mo-Ti mixed oxide catalysts prepared by a homogeneous precipitation method for selective catalytic reduction of NO with NH3[J]. J Taiwan Inst Chem E,2018,86:133−140. doi: 10.1016/j.jtice.2018.02.027 [126] LI L L, LI P X, TAN W, et al. Enhanced low-temperature NH3-SCR performance of CeTiOx catalyst via surface Mo modification[J]. Chin J Catal,2020,41(2):364−373. doi: 10.1016/S1872-2067(19)63437-6 [127] JING DI C, HONG H, LI YUN S, et al. Promotional effect of Pr-doping on the NH3-SCR activity over the V2O5-MoO3/TiO2 catalyst[J]. Chem J Chin Univ,2015,36(3):523−530. [128] YU C, HUANG B, DONG L, et al. Effect of Pr/Ce addition on the catalytic performance and SO2 resistance of highly dispersed MnOx/SAPO-34 catalyst for NH3-SCR at low temperature[J]. Chem Eng J,2017,316:1059−1068. doi: 10.1016/j.cej.2017.02.024 [129] HOU X, CHEN H, LIANG Y, et al. Pr-doped modified Fe-Mn/TiO2 catalysts with a high activity and SO2 tolerance for NH3-SCR at low-temperature[J]. Catal Lett,2020,150(4):1041−1048. doi: 10.1007/s10562-019-03019-8 [130] ZHAI G P, HAN Z T, WU X T, et al. Pr-modified MnOx catalysts for selective reduction of NO with NH3 at low temperature[J]. J Taiwan Inst Chem E,2021,125:132−140. doi: 10.1016/j.jtice.2021.06.008 [131] 李祥超. 水泥工业脱硝技术及路线[J]. 中国水泥,2022,(4):82−86.LI Xiangchao. Denitrification technology and route of cement industry[J]. China Cement,2022,(4):82−86. [132] WANG H, HUANG B, YU C, et al. Research progress, challenges and perspectives on the sulfur and water resistance of catalysts for low temperature selective catalytic reduction of NOx by NH3[J]. Appl Catal A: Gen,2019,588:117207. doi: 10.1016/j.apcata.2019.117207 [133] JIN R, LIU Y, WANG Y, et al. The role of cerium in the improved SO2 tolerance for NO reduction with NH3 over Mn-Ce/TiO2 catalyst at low temperature[J]. Appl Catal B: Environ,2014,148:582−588. [134] 边雪, 肖坤宇, 王书豪, 等. xCeO2-yWO3-TiO2脱硝催化剂抗SO2性能研究[J]. 稀有金属,2020,44(9):974−980.BIAN Xue, XIAO Kunyu, WANG Shuhao, et al. Study on SO2 resistance of xCeO2-yWO3-TiO2 denitrification catalyst[J]. Chin J Rare Metals,2020,44(9):974−980. [135] TAN W, LIU A, XIE S, et al. Ce-Si mixed oxide: A high sulfur resistant catalyst in the NH3-SCR reaction through the mechanism-enhanced process[J]. Environ Sci Technol,2021,55(6):4017−4026. doi: 10.1021/acs.est.0c08410 [136] 魏永林, 陈红萍, 侯欣辛, 等. 低温脱硝催化剂抗硫性能研究[J]. 河北冶金,2021,(2):1−6.WEI Yonglin, CHEN Hongping, HOU Xinxin, et al. Research on sulfur resistance of low-temperature denitrification catalyst[J]. Hebei Metallurgy,2021,(2):1−6. [137] TAN W, WANG J, LI L, et al. Gas phase sulfation of ceria-zirconia solid solutions for generating highly efficient and SO2 resistant NH3-SCR catalysts for NO removal[J]. J Hazard Mater,2020,388:121729. doi: 10.1016/j.jhazmat.2019.121729 [138] FRANCE L J, YANG Q, LI W, et al. Ceria modified FeMnOx-enhanced performance and sulphur resistance for low-temperature SCR of NOx[J]. Appl Catal B: Environ,2017,206:203−215. doi: 10.1016/j.apcatb.2017.01.019 [139] WANG F, SHEN B, ZHU S, et al. Promotion of Fe and Co doped Mn-Ce/TiO2 catalysts for low temperature NH3-SCR with SO2 tolerance[J]. Fuel,2019,249:54−60. doi: 10.1016/j.fuel.2019.02.113 [140] 王新频, 赵娇, 乔彬, 等. 国内外水泥熟料生产线降氮脱硝技术及应用(下)[J]. 中国水泥,2016,(10):8.WANG Xinfin, ZHAO Jiao, QIAO Bin, et al. Technology and application of nitrogen and nitrate reduction in cement clinker production line at home and abroad[J]. China Cement,2016,(10):8. [141] 吕洪炳, 胡晨晖, 刘春红, 等. 超低温SCR脱硝催化剂抗水性研究进展[J]. 能源工程,2022,42(6):52−56.LV Hongbing, HU Chenhui, LIU Chunhong, et al. Research progress on water resistance of ultra-low temperature SCR denitrification catalysts[J]. J Energ Eng,2022,42(6):52−56. [142] YU S, JIANG N, ZOU W, et al. A general and inherent strategy to improve the water tolerance of low temperature NH3-SCR catalysts via trace SiO2 deposition[J]. Catal Commun,2016,84:75−79. doi: 10.1016/j.catcom.2016.06.001 [143] XU Y C, WANG P C, PU Y J, et al. MnCe/GAC-CNTs catalyst with high activity, SO2 and H2O tolerance for low-temperature NH3-SCR[J]. Sep Purif Technol, 2023, 305. [144] LIAN Z, LIU F, HE H, et al. Manganese-niobium mixed oxide catalyst for the selective catalytic reduction of NOx with NH3 at low temperatures[J]. Chem Eng J,2014,250:390−398. doi: 10.1016/j.cej.2014.03.065 [145] QIU M, ZHAN S, YU H, et al. Facile preparation of ordered mesoporous MnCo2O4 for low-temperature selective catalytic reduction of NO with NH3[J]. Nanoscale,2015,7(6):2568−2577. doi: 10.1039/C4NR06451H [146] JIANG H, WANG J, ZHOU J, et al. Effect of promoters on the catalytic performance and SO2/H2O resistance of α-MnO2 catalysts for low temperature NH3-SCR[J]. Ind Eng Chem Res,2019,58(4):1760−1768. doi: 10.1021/acs.iecr.8b05009 [147] LIU S M, GUO R T, WANG S X, et al. Deactivation mechanism of Ca on Ce/TiO2 catalyst for selective catalytic reduction of NOx with NH3[J]. J Taiwan Inst Chem E,2017,78:290−298. doi: 10.1016/j.jtice.2017.06.019 [148] WANG S X, GUO R T, PAN W G, et al. The deactivation of Ce/TiO2 catalyst for NH3-SCR reaction by alkali metals: TPD and DRIFT studies[J]. Catal Commun,2017,89:143−147. doi: 10.1016/j.catcom.2016.11.005 [149] 沈伯雄, 卢凤菊, 高兰君, 等. 中温商业SCR催化剂碱和碱土中毒特性研究[J]. 燃料化学学报,2016,44(4):500−506.SHEN Boxiong, LU Fengju, GAO Lanjun, et al. Alkaline and alkaline earth poisoning characteristics of commercial SCR catalysts at medium temperature[J]. J Fuel Chem Technol,2016,44(4):500−506. [150] SHI X H. The poisoning effect of Na~+ and Ca~(2+) ions doped on the V2O5/TiO2 catalysts for selective catalytic reduction of NO by NH3[J]. Appl Catal B: Environ,2010,94(1):71−76. [151] LI M Y, GUO R T, HU C X, et al. The enhanced resistance to K deactivation of Ce/TiO2 catalyst for NH3-SCR reaction by the modification with P[J]. Appl Surf Sci,2018,436(APR.1):814−822. [152] CAO J, YAO X, CHEN L, et al. Effects of different introduction methods of Ce4+ and Zr4+ on denitration performance and anti-K poisoning performance of V2O5-WO3/TiO2 catalyst[J]. J Rare Earth,2020,38(11):1207−1214. doi: 10.1016/j.jre.2019.11.005 [153] CAO J, YAO X, YANG F, et al. Improving the denitration performance and K-poisoning resistance of the V2O5-WO3/TiO2 catalyst by Ce4+ and Zr4+ co-doping[J]. Chin J Catal,2019,40(1):95−104. doi: 10.1016/S1872-2067(18)63184-5 [154] PENG Y, LI J, SI W, et al. Ceria promotion on the potassium resistance of MnOx/TiO2 SCR catalysts: an experimental and DFT study[J]. Chem Eng J,2015,269:44−50. doi: 10.1016/j.cej.2015.01.052 [155] LIU X, GAO J, CHEN Y, et al. Rational design of alkali-resistant NO reduction catalysts using a stable hexagonal V-Doped MoO3 support for alkali trapping[J]. ChemCatChem,2018,10(18):3999−4003. doi: 10.1002/cctc.201800818 [156] HAO Z, SHEN Z, LI Y, et al. The role of alkali metal in α-MnO2 catalyzed ammonia-selective catalysis[J]. Angew Chem Int Ed,2019,131(19):6417−6422. doi: 10.1002/ange.201901771 [157] LI X, LI X, LI J, et al. High calcium resistance of CeO2-WO3 SCR catalysts: Structure investigation and deactivation analysis[J]. Chem Eng J,2017,317:70−79. doi: 10.1016/j.cej.2017.02.027 -

下载:

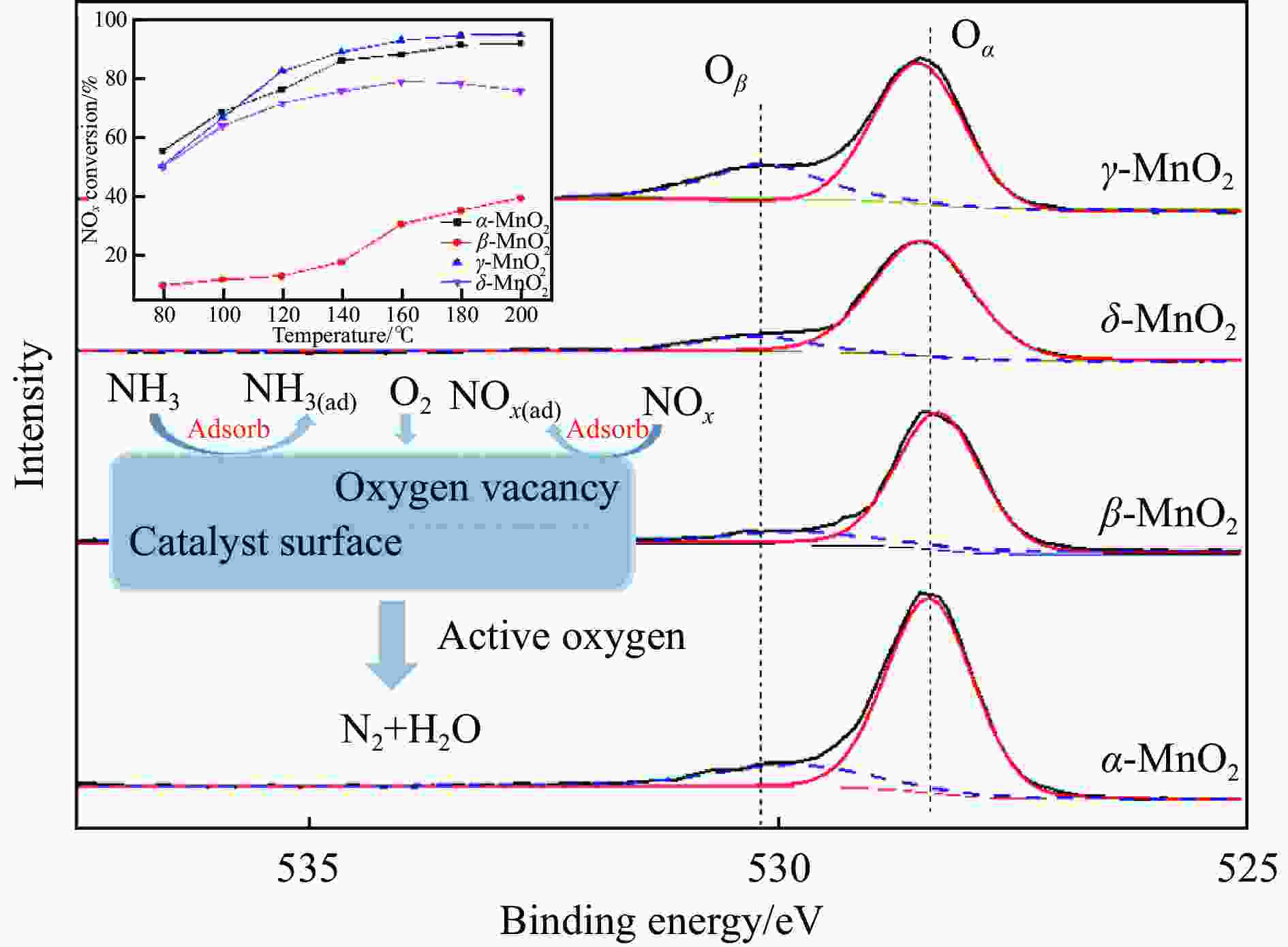

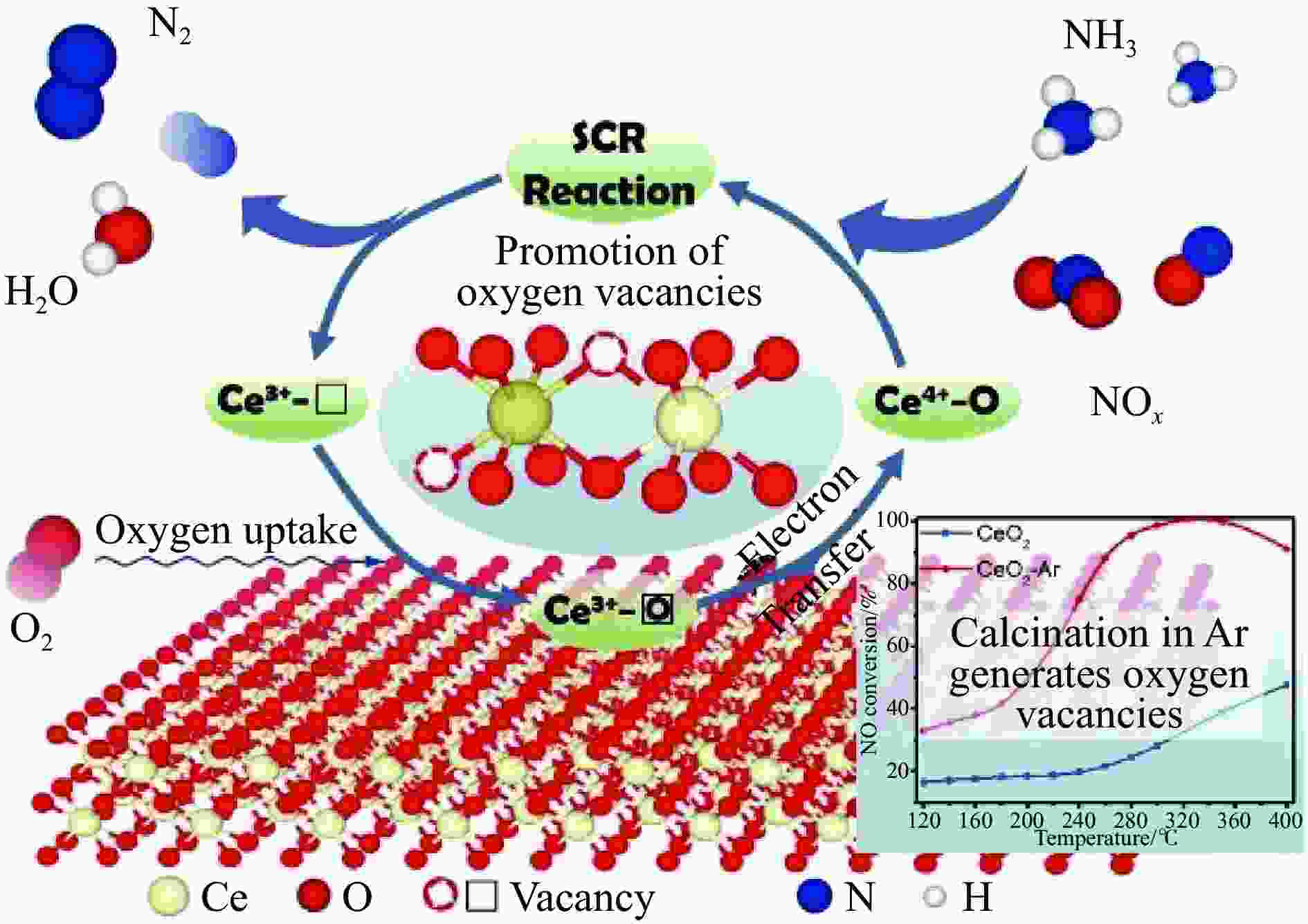

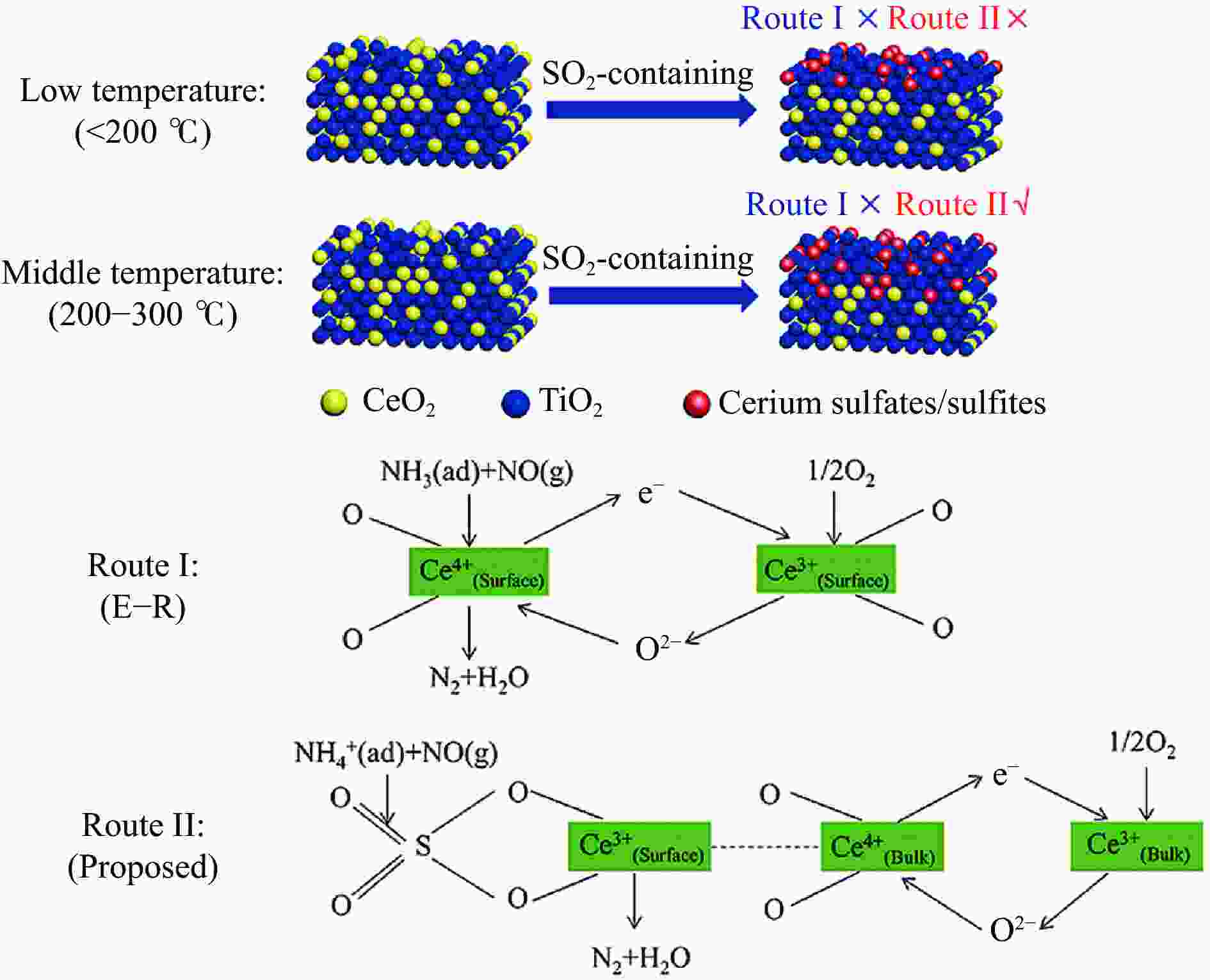

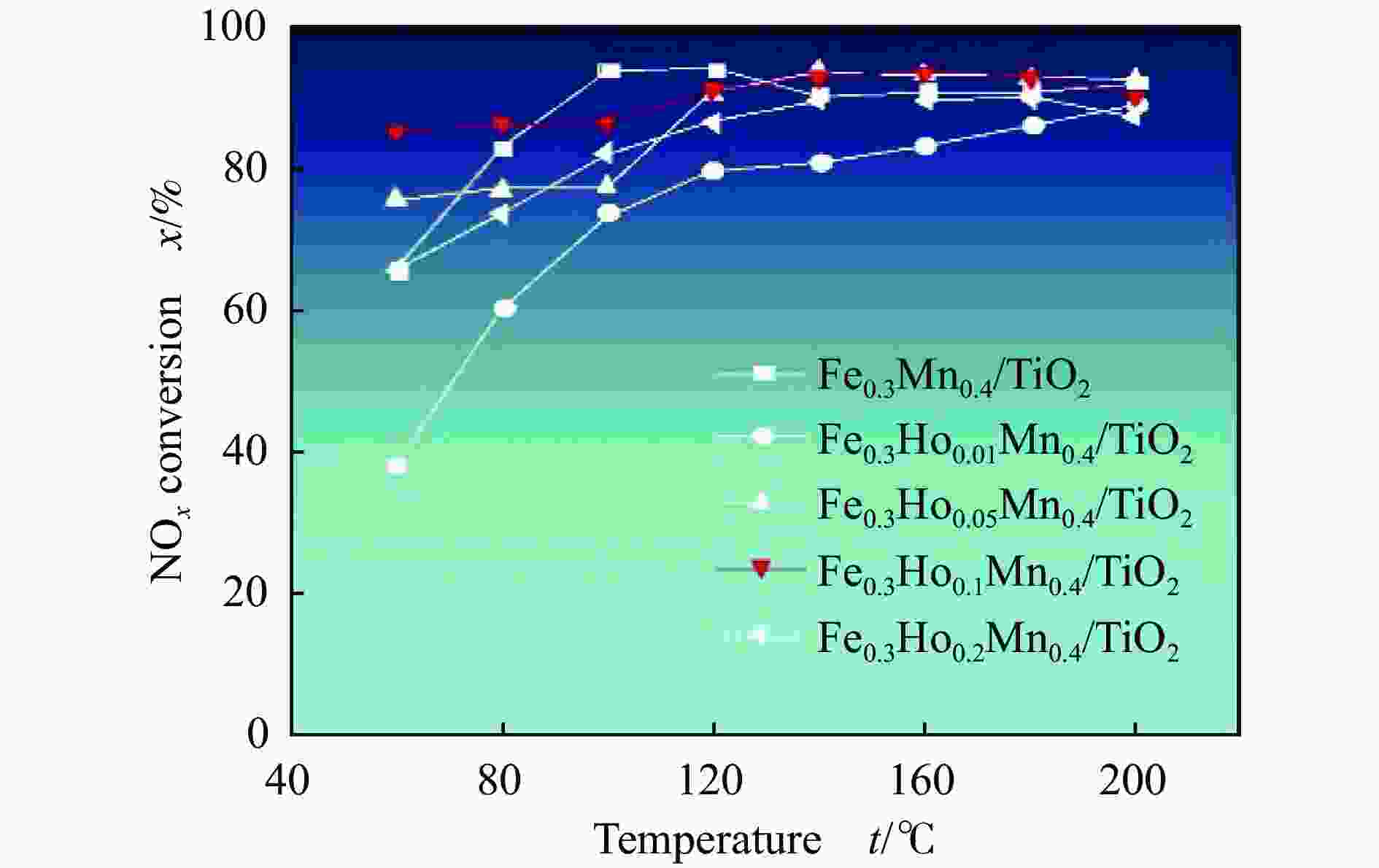

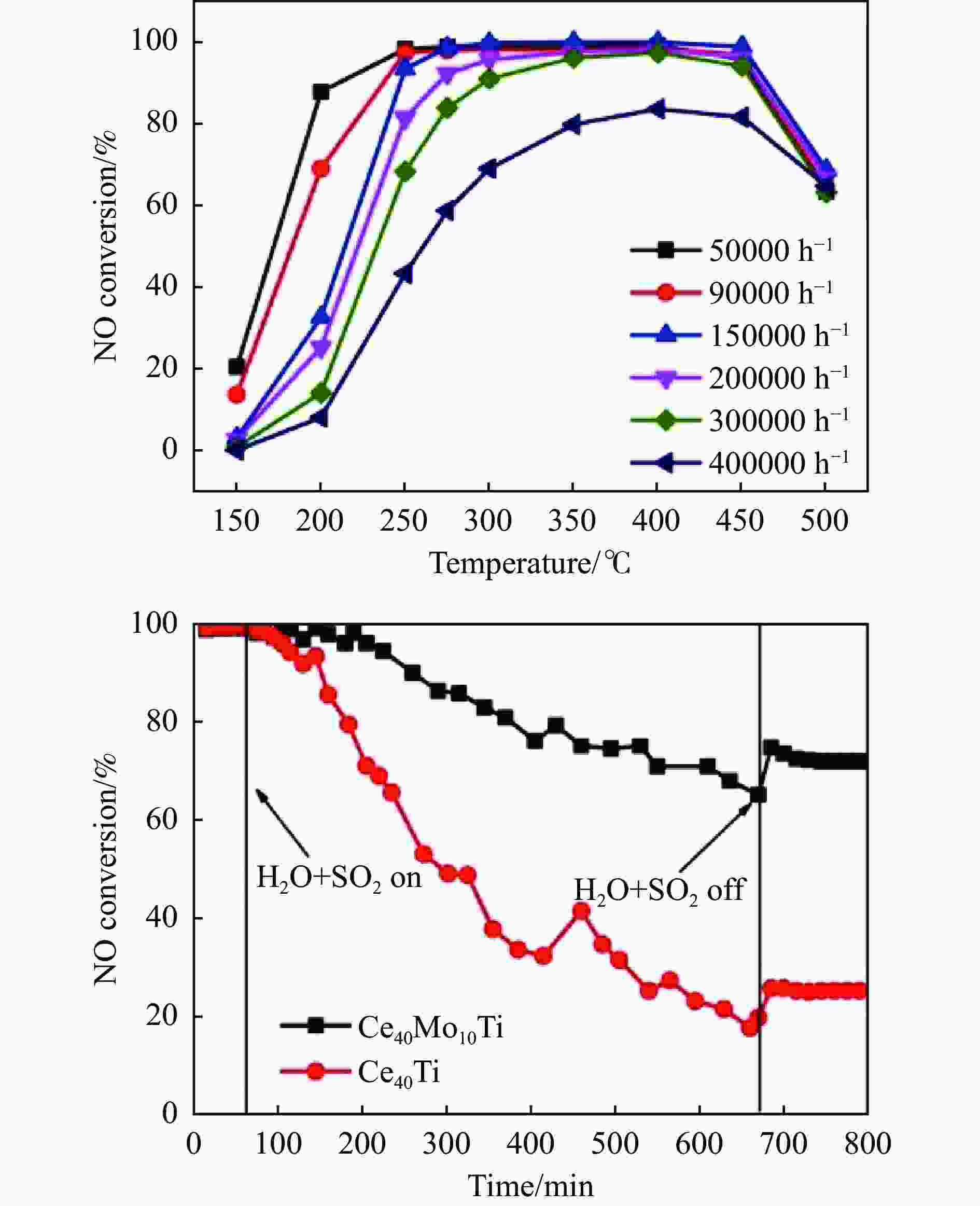

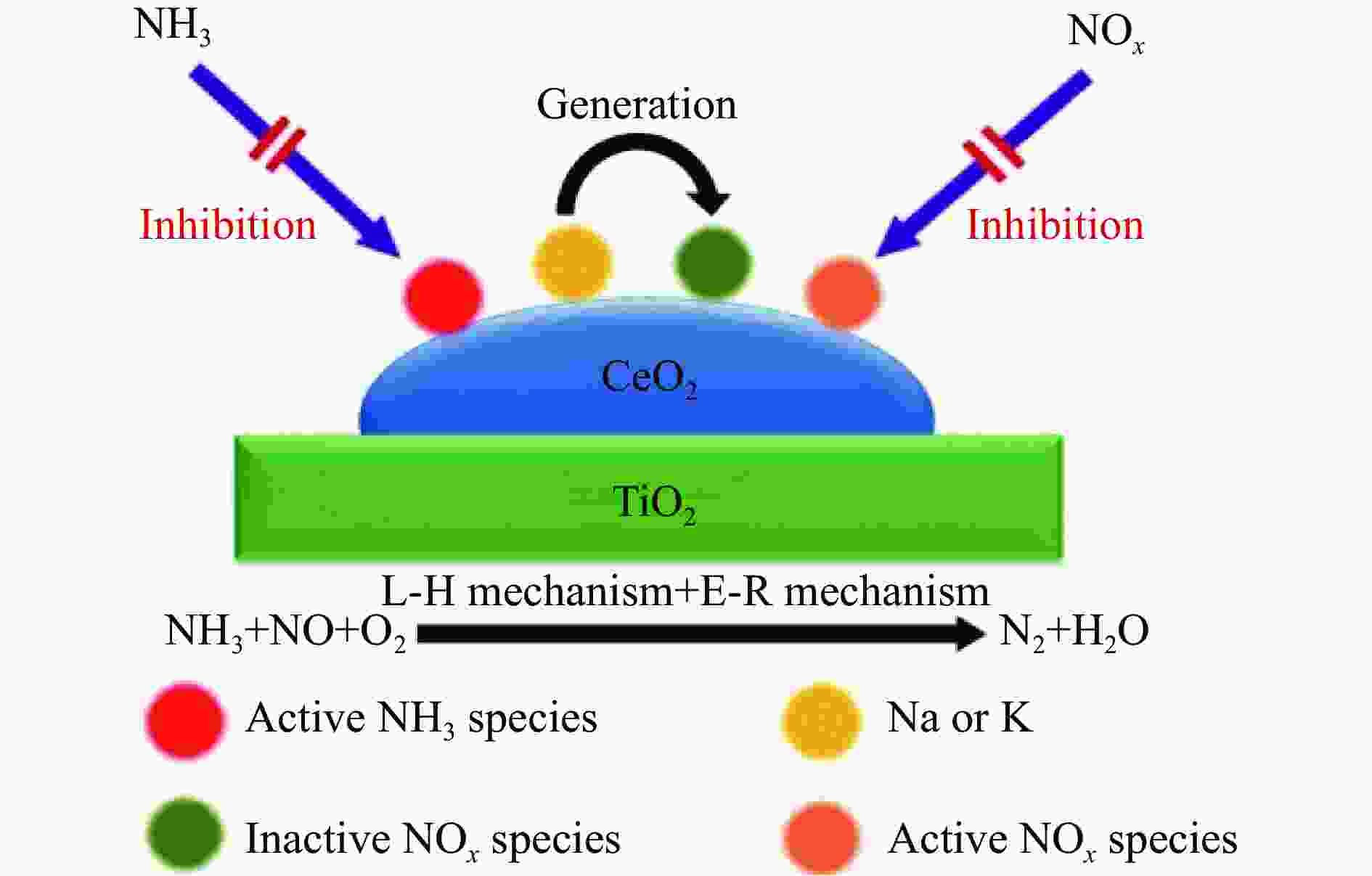

下载: